The Importance of Equipment Maintenance

January 20, 2025

January 20, 2025

Updated: 1/20/25

Jump To Sections:

- Types of Maintenance

- Benefits of Proper Equipment Maintenance

- Challenges of Heavy Machinery Maintenance

- Heavy Equipment Maintenance Checklist

Underestimating the importance of equipment maintenance is taking a toll on your bottom line. The saying “if it isn’t broke, don’t fix it” is too often the way some view construction equipment maintenance. Why would you pay for service on your equipment if there’s nothing wrong with it? Believe it or not, there are several reasons.

Construction equipment is an investment — one that requires time and money to keep in optimal shape. The importance of preventative maintenance directly connects to efficient and safe operation around the worksite.

What Is Equipment Maintenance, and Why Is It Important?

Maintaining your construction equipment is a proactive approach to keep your operation’s most crucial tools in top condition and ready to support your biggest projects. This cost-effective strategy minimizes your risk of costly downtime or expensive repair requirements that could impact your on-the-job performance.

When you invest in maintenance, you’ll:

- Keep equipment running efficiently: Maintenance solutions are designed to keep your equipment running at its peak performance. Taking attentive care of your assets extends their service life to create a more productive workflow with less frequent repairs and replacements.

- Avoid growing problems: Small issues always pose a risk of growing into larger, more expensive problems that can lead to project delays. Investing in maintenance will ensure every component is in good health and ready to work reliably.

- Save money: Waiting to repair your machines until they’re broken will likely lead to high costs. Regular service helps you avoid these expenses to put more money back in your pocket.

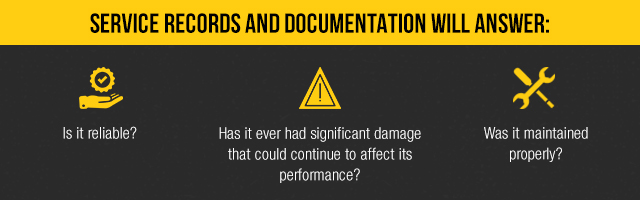

- Boost resale value: If you think you might sell your equipment in the future, it’s wise to keep it in top condition with maintenance. The better condition your machines are in and the more service records you have, the larger the price you can convince buyers to pay.

- Enhance safety: Breakdowns or malfunctions run the risk of workplace injuries and fatalities. Equipment maintenance is one of the best proactive steps you can take to protect your operators.

- Maximize warranty coverage: Many equipment warranties require regular service to continue coverage. Taking your equipment into the shop every now and then will give you the peace of mind that your warranty is intact if significant issues were to arise.

- Prevent excessive downtime: Performing regular and routine maintenance tasks ensures your machines run reliably. This dependability can prevent malfunctions or failures that have the potential to interrupt and delay your projects, helping you limit additional expenses.

Types of Maintenance

When it comes to the upkeep of heavy construction equipment, there are a few different kinds of maintenance that help a machine perform at its best. Here are the main types to prioritize:

Preventative Maintenance

Preventative maintenance involves regularly scheduled inspections and tune-ups to address anything that may turn into an issue in the future. The purpose of this type of maintenance is to catch failures before they happen.

You can save costs over time with regular preventative services as they can help avoid the need for expensive repairs and replacements down the line. Utilizing preventative maintenance to repair before failure can also greatly minimize costly unscheduled downtime.

Corrective Maintenance

Corrective maintenance refers to services you’ll need when something on your equipment breaks or malfunctions. This type of maintenance is also referred to as repair.

When a machine fails to operate properly, a technician will address the problem and decide if it needs a repair or replacement part. If broken parts are not taken care of with corrective maintenance, damage can spread to secondary systems and lead to greater expenses.

Predictive Maintenance

Predictive maintenance foreshadows an equipment failure through close monitoring and data collection via technology. The data will indicate when maintenance is needed to prevent issues before they occur.

Unlike preventative maintenance, this type does not require a pre-planned schedule. Instead, operators will wait for the technology to indicate that service is needed before taking action.

CHALLENGES OF HEAVY MACHINERY MAINTENANCE

The following are some of the top challenges associated with managing maintenance efforts for heavy equipment:

- Costs: Construction equipment is an investment, and it is essential to protect that investment with ongoing maintenance efforts. It gets complicated knowing when to spend money on ongoing repairs and when to replace a piece of equipment entirely.

- Scheduling: Another challenge can be finding the right time for maintenance services. You’ll want to ensure your machine is ready when you need it and that maintenance is scheduled at opportune times to avoid project downtime.

- Skilled personnel: If you have an immediate maintenance need, you’re also going to require someone who is both trained on the specific piece of equipment and available to help.

- Documenting maintenance history: It can be difficult to keep a well-organized history of maintenance tasks, big and small, for every piece of heavy equipment you work with. Documenting this information is essential for maintaining your machines’ value and warranties.

CONSTRUCTION EQUIPMENT MAINTENANCE CHECKLIST

Realizing the importance of equipment maintenance is only the first part. The second part is knowing what to do to ensure you’re maximizing the life of your equipment. There are several tips you can use to extend the operating life of your machine, regardless of what type of equipment you have or the size of your fleet.

MONITOR EQUIPMENT TECHNOLOGY

This seems like a no-brainer, but equipment technology has come a long way. Many models have a variety of sensors in place that will tell you if something isn’t working properly, even if it’s something small. Make sure someone is monitoring the technology and collecting data on equipment and performance. This technology is only valuable if someone is there to bring it to your attention when a sensor detects something isn’t working right.

There are also tools you can use to supplement the technology a particular piece of equipment has.

The following can help you collect additional information on your equipment so that you have real-time information on each machine’s condition:

- Vibration monitoring

- Thermal imaging

- Audio gauges

TRAIN OPERATORS AND TECHNICIANS

Regardless of how many different technologies are available, there is no substitution for the human touch. After all, what good is the technology if no one is proactively monitoring and testing it? It takes a trained operator to understand the problem and a trained technician to know how to fix it or to alert someone that it needs repair. Educating your equipment operators and any technicians you have on staff is key to extending the life of your equipment, as their hands-on experience can provide an early warning and ensure that small problems don’t turn into big ones.

Training staff can also help prevent repairs due to misuse or overuse of equipment. Operators need to be trained on the specific model of equipment they will be using. If in-person training isn’t feasible, there needs to be a summary of best practices and an operation manual in place so you can ensure operators are using the equipment the way it was meant to be used. An untrained equipment operator could unintentionally cause costly repairs, so make sure the best practices and expectations are outlined clearly — not only on training day — but also reinforced on a regular basis.

SET AN EQUIPMENT MAINTENANCE SCHEDULE AND STICK TO IT

Every piece of equipment is different. They all have their own intricacies and need a maintenance and repair schedule to match. Over time, some seals, belts, bolts and other components will wear down and experience damage, which may lead to expensive repairs and extensive downtime. Swapping them out before they become an issue will keep your operations running according to schedule and help you avoid any headaches down the line.

Most equipment comes with original equipment manufacturer (OEM) maintenance recommendations you should use to inform the frequency of your service. While it may seem strange to fix something that isn’t broken, this type of preventative maintenance is a crucial step toward getting the most life out of your equipment.

PERFORM ROUTINE INSPECTIONS

Detailed equipment inspections should occur every time a machine is used, checking components like seatbelts, hoses, and wiring for wear or cracks. You should conduct these checks separately from your maintenance schedule to have a clear picture of your equipment’s condition at all times. Routine inspections allow you to better understand how your equipment is handling its age, as well as on-the-job vibrations, high temperatures and friction.

Inspections are key to extending equipment life. Performing thorough visual inspections empowers your team to find even the smallest issues, such as cracked seals or loose bolts, and fix them before they become serious or expensive. We also recommend keeping up with more extensive inspections that may be a part of your OEM maintenance plan.

ADD LUBRICANTS

Lubrication is key in any equipment. It reduces friction between moving parts and can extend the life of heavy construction equipment. Get to know each piece of equipment you have and what type of lubricant each of them requires.

Lubrication is not a one-size-fits-all substance, so make sure you talk to a knowledgeable dealer to determine the manufacturer’s recommendations for oil, grease and other lubricants. Know where you can and cannot add lubricant, as there may be some places you’re able to check and add on your own between scheduled maintenance, but some may require a trained technician.

Get to know your equipment and make sure you keep things lubricated over time. Friction due to a lack of lubrication can drastically reduce the life of your equipment.

TEST LUBRICANTS

Lubrication is the key to more than just reducing friction and wear and tear. It can also be a valuable tool in finding problem areas. Learning what parts of your equipment use lubrication and are accessible can help you identify issues.

Look for a buildup of oil or grease on seals, hoses and other connections, and check for leaks on the machine and on the ground. You can also check lubricants to discover parts of your construction equipment that may be worn down. Analyzing particles in used oil, for example, can reveal contaminants that show a breakdown in potentially unseen areas.

Not an oil expert? That’s not a problem. A knowledgeable Warren CAT technician can perform a fluid analysis for you and you can request a fluid analysis any time from the Warren CAT Fluids Lab on any kind of machinery – not just Cat equipment. This is usually a part of scheduled maintenance, but it’s also something you can check if you suspect there’s something wrong or want to better understand the health of your machine.

KEEP EQUIPMENT CLEAN

Construction equipment, regardless of its size or weight, is still vulnerable to dirt and contaminants. These machines rely on complex systems made of many moving parts. Simple tasks, like changing filters and cleaning electronic components, can improve your equipment’s operation and decrease the likelihood of expensive repairs. It’s wise to store your machines in secure areas away from the elements when they’re not in use.

USE GENUINE OEM PARTS

Why use genuine OEM Cat parts when you can get the same part from another company for less money? This is a legitimate question and one we hear often. It’s not a secret that you can find the same part for a cheaper price.

Let’s take something small and simple — a bolt, for example. If you’re looking for something small like a bolt, is it really that important to have the OEM bolt replacement? Let’s say you’ve found a cheaper option. Ask yourself a few questions:

- Do you know it’s made from the exact same material composition as the original?

- Do you know if it has the exact same thread pitch?

- Does your warranty require OEM parts?

- Is that bolt compatible with the sensors in place to check that part of the equipment is working?

- Are you guaranteed to get that bolt within a certain timeframe?

- Are you confident in the chemical makeup of the bolt and that it will resist corrosion the same as the original?

Obviously, a bolt is a simple example, but if we have this many questions about a bolt, is it worth the risk, especially when it comes to a more complex part? The last thing you want is to void your warranty to save money on a part or to be left with additional downtime when it doesn’t arrive in a timely fashion.

Your equipment manufacturer spent a lot of time formulating that exact part for your piece of equipment, so in the interest of extending equipment life, choose genuine OEM parts.

Warren CAT Has Your Back

Count on the team at Warren CAT to help you effectively navigate every challenge associated with maintaining your construction equipment. We have the expertise and the resources backed by 40 years of industry experience to be your reliable source for full-service maintenance and repairs. We strive to deliver cost-efficient solutions that maximize the life of your equipment and keep your projects moving forward. Our flexible Customer Service Agreements (CVAs) drive our mission with affordable preventative maintenance plans to help you manage your fleet and prevent costly repairs.

Our service providers are highly skilled Cat technicians who receive state-of-the-art training. They are educated and have the resources available to find the fastest and most cost-effective solution to get your equipment back to you in optimal working condition. Our field service team has the ability to get to your job site quickly with our 24-hour emergency services, working quickly to get your machines back to their best in no time.

To learn more about the specific types of service we offer, visit the equipment services section of our website. Contact us to learn more about how partnering with a local dealer can help save you time and money when it comes to your fleet of equipment.

CONTACT WARREN CAT TO LEARN MORE

At Warren CAT, we have the expertise and tools to keep your construction equipment running at its best. Our skilled service technicians can provide preventative maintenance and repair services to help you minimize expensive downtime and boost productivity.

Are you ready to maximize the life of your equipment and keep it operating at peak performance? Contact Warren CAT to learn more about partnering with us for your maintenance needs today!