12 Ways to Prevent Equipment Theft

March 17, 2025

March 17, 2025

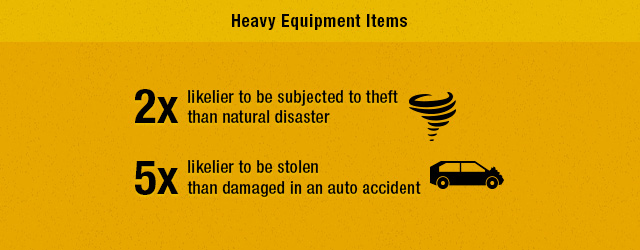

Thousands of machines are stolen every year, resulting in hundreds of millions of dollars worth of lost assets for businesses across the United States. These costs only continue to grow with extensive downtime and replacement expenses, leading to decreased efficiency and lost revenue.

Boosting your security will ensure you treat your equipment with the care it deserves and show funding agencies you’re safe to work with.

Types of Construction Theft

Whether you’re paving roads, erecting buildings or working around the farm, your equipment is an essential component to getting the job done right. However, with increasing theft rates around the country, your most important tools could be at risk. Tractors, utility vehicles, backhoe loaders, excavators, dozers and wheel loaders are some of the most at-risk models for being stolen, which may encompass:

- Whole equipment: Thieves steal the entire machine from the premises.

- Component: Criminals remove specific, high-value components such as engines, hydraulic parts and attachments.

- Unauthorized use: Someone uses your equipment without your permission or knowledge, potentially causing expensive damage or wear and tear.

CONSTRUCTION EQUIPMENT THEFT PREVENTION METHODS

With rising numbers of stolen equipment, construction equipment theft prevention has become a growing concern among fleet owners nationwide. Decision-makers wanting to minimize the risk of theft on their sites should consider the following precautions.

1. KNOW WHAT DRIVES CONSTRUCTION EQUIPMENT THEFT

The construction equipment theft market is a $300 million to $1 billion industry. In a nutshell, equipment theft is driven by easy access and resale value. Brand name, good condition and easily accessible pieces of equipment are often easy targets.

The market for equipment theft is due to several factors, including:

- The commanding rate of items and parts

- A lack of surveillance on jobsites

- For thieves, the ability to evade capture

- The simple process of selling stolen parts

- A negligible likelihood of detection

- Soft sentences for those who are actually caught

2. KEEP RECORDS OF ALL EQUIPMENT

On most equipment, serial numbers and Part Identification Numbers (PINs) are either nonexistent or non-standardized. Consequently, a thief can clear away the identity of a stolen piece of equipment by simply having it swapped or wiped. For that reason, it’s crucial to familiarize yourself with identifying information and maintain proof of ownership, from manufacturer, model and serial number to the date you bought each piece of equipment or part.

Keep records and take photographs of your entire fleet. Offering the police and the NICB this kind of information will aid in their search to successfully find and return any stolen equipment.

3. PAY ATTENTION TO EQUIPMENT THEFT TRENDS

While it’s important to look after all the equipment in your fleet, you should be especially aware of which types are the most common targets for theft. In the Southwestern U.S., for instance, the most frequently targeted worksite machines include tractors, skid steers and backhoes. In the Western portion of the country, thefts of backhoe units have been on the rise.

In the past, breaker/hammer attachments have been a common target among thieves, and while the trend has dipped, such equipment should still be protected with utmost diligence. With improved awareness of trends on the black market, it’s easier to point out suspect behavior the moment it occurs within a fleet. Regardless of what items are most or least likely to be targeted, don’t allow trends to serve as a fake indicator of whether or not a given item is vulnerable to theft.

4. SECURE YOUR FLEET FROM INTRUSION

Criminals are often looking to get in and out quickly. One of the best strategies to deter these criminals is to set up fencing surrounding your equipment. Using chain link fences, lockable gates and fence covers will help shield your most valuable tools and make your storage less attractive to criminals. Here are some other ideas to strengthen your site:

- When you finish work for the day, park all equipment in an inward-facing circle, with small machinery in the center.

- Have surveillance cameras and/or motion detectors installed at the location.

- See if you can get local law enforcement to patrol the area with greater frequency during off hours, especially if your site is in a high-theft area.

If your site looks even slightly more secure than average, a lot of thieves will skip it for a more vulnerable location.

5. USE ANTI-THEFT TRACKING DEVICES AND RECOVERY SYSTEMS

Aside from sitewide security measures, add individual security precautions. Many machines may benefit from heavy equipment anti-theft devices like wheel or ignition locks, battery switches or shut-off systems. You can take your protection to the next level by removing circuit breakers and fuses from your machines when they’re not actively being used.

This is not to say that deactivators serve as foolproof theft preventers; while the aforementioned options can thwart a lot of attempts, skilled thieves will sometimes know their way around such deterrents. Stolen machines have a much greater chance of being recovered when linked to a GPS tracking system, which would give police the ability to pinpoint the equipment’s whereabouts.

If you’re looking for a product that will make it possible to track the productivity and whereabouts of the machines in your fleet at all times, the Cat VisionLink® will have you covered. With VisionLink, you can view a piece of equipment’s fuel usage, idle time, movements and location from any computer, laptop or digital handheld.

6. USE NIGHTTIME CAMERAS, MOTION SENSORS AND/OR LIGHT TOWERS

Visibility is crucial to understanding where your equipment is at all times. A digital, wireless video system can add clear and interference-free nighttime security to any worksite location. These systems can be set to turn on when motion is detected or to record continuously throughout the night. It’s wise to invest in multiple cameras, giving your team several views of your equipment storage space to ensure every corner is covered.

If you store equipment in a wide open space, a light tower could be a welcome addition to your security strategy. Some light towers can be as tall as 30 feet high and rotate to shine a light across every part of your space.

7. HIRE PRIVATE NIGHT GUARDS FOR AFTER-HOURS SURVEILLANCE

Depending on how much you’re willing to invest in the overnight security of your equipment, an onsite security guard could be invaluable. Some worksites hire their own security personnel, who sometimes learn on the job and only possess minimal capabilities. Other worksites hire security guards from private companies, where guards are trained for emergency situations and are licensed to carry weapons. Some guards even come from police or military backgrounds and have extensive training in handling armed theft and other emergency scenarios.

Of course, it takes a certain kind of person to work an overnight shift. He or she will need to adjust to a nocturnal schedule, which can have its own issues due to the social limitations that this type of lifestyle can impose on an individual. A guard with daytime experience might need special nighttime training to know how to monitor intrusions, theft, and other illegal activities that occur in the dark. It’s also important for a guard to know local police protocol, especially in the event of a major, multi-man break-in or theft that could require emergency backup. Whether or not you choose to employ armed guards, they may still need to be licensed to drive commercial equipment depending on the overall scope of the job.

8. KEEP EMPLOYERS UP-TO-DATE ON SECURITY PRACTICES

At any worksite location, employees and equipment operators can do their part to ensure the security of equipment on site. It’s important to train them on the aspects of security that might not be obvious from their general area of expertise, such as spotting suspicious activity on the premises. For their part, operators should log each used piece of equipment at the end of each shift and park all construction equipment securely according to site protocol. Each operator should also be aware of the unique identifiers on otherwise identical vehicles.

9. MOVE YOUR EQUIPMENT TO A SAFER LOCATION DURING OFF-HOURS

If you’re unable to set up any of the aforementioned safeguards like fences, surveillance or a deal with local police patrol, look for a safer storage area within driving distance from your worksite. While it could run you a bit more in terms of gas money and shutdown/startup time, it’s worth the extra effort when it comes to preventing theft.

10. IMMEDIATELY REPORT A THEFT UPON DISCOVERY

In any given theft scenario, notify the police the moment it comes to your attention. Belated reports of stolen equipment are the primary reason why so few items are ever recovered. Therefore, the quicker you report the theft of one of your worksite equipment, the likelier it will be recovered by investigators.

If you find your fleet hit by an equipment theft, take the four following actions as soon as possible to improve your odds of recovery:

- If you’ve entered the item into an equipment tracking system, look for its whereabouts via the map feature. The Cat® Product Link is one of the best products for these functions.

- Call the authorities and tell them all the details about the missing machine, such as its color, size, model, attachments, last-verified location, etc. Provide as much detail as possible; the more information the investigators have to go on, the likelier your machine will be found.

- Inform your insurance company about the situation, allowing it to get started right away on your claim.

- Report the theft of your machine to the National Equipment Registry (NER).

Remember, the success of a theft investigation can largely depend on how soon an item is reported missing and how much information is given to help it get identified.

11. GIVE EACH MACHINE A RECOGNIZABLE INDICATOR

Worksite equipment tends to look quite similar, which can make it difficult for the police to identify your stolen equipment in the case of theft. Machinery isn’t required to have a registration or titles, so adding labels, symbols or names to a machine can be helpful in recovering a piece of equipment. Stamp or engrave your identifier to ensure it cannot be easily removed.

12. MAKE THEFT PREVENTION ONE OF YOUR TOP PRIORITIES

Losing your construction equipment to thieves will happen when you least expect it and could leave your operations on pause. Without proper attention to your security and preventative measures, you’ll deal with frustrating downtime, headaches and lost revenue in the long run. Instead, fleet managers can take proactive steps to prevent construction equipment theft and remain focused on what they do best — running their businesses.

EQUIPMENT THEFT STATS AND TRENDS ACROSS THE U.S.

Construction equipment includes some of the most expensive machine types out there. Because of this prevalence, thefts continue to rise year after year, posing significant threats to job sites around the country. The National Equipment Register tracks these thefts closely and estimates around 11,000 machines are stolen every year at the time of publication. Since these tools often come with higher price tags, these thefts add up to between $300 million and $1 billion every year, while averages tend to stay around $400 million.

According to the 2016 report published by the NICB, the most valuable equipment being stolen includes loaders (18%), tractors (14%) and riding mowers (41%). The report suggests that machinery equipped with wheels is most often sought after due to ease of transport.

Other popular targets for robberies include tractors, backhoes, and utility vehicles. The most popular machine brands include John Deere (2,420), Kubota (1,315), Bobcat (882), Cat (773) and Toro (368). These thefts are occurring in certain states more than others, with a high frequency in states like Texas (2,375), North Carolina (796), Florida (763), California (694) and Georgia (577).

Certain reports also show increases in construction equipment thefts around certain holidays, such as the Fourth of July and Labor Day. Texas is one of the most targeted states as of 2024 around this time of the year, with utility vehicles, skid steers and mowers among the most wanted. With all this in mind, it’s crucial to devise a sound protection plan to ensure your machinery is secure.

Improve Sitewide Security With Warren CAT

Security is a huge part of maintaining efficient and profitable operations. At Warren CAT, we understand this importance and strive to offer meaningful solutions you can trust to keep your projects running on schedule. To learn more about VisionLink and other products for preventing construction equipment theft, large and small, contact Warren CAT today.