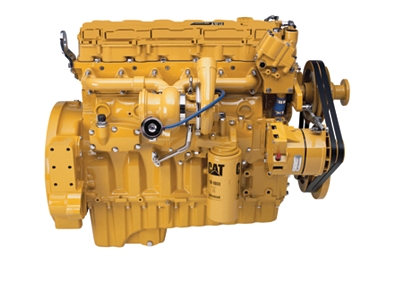

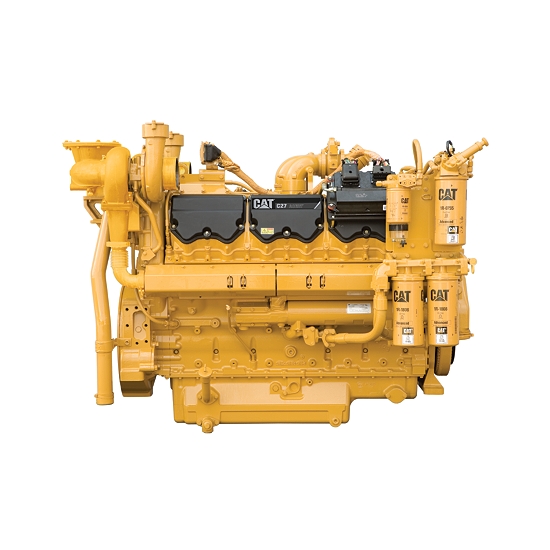

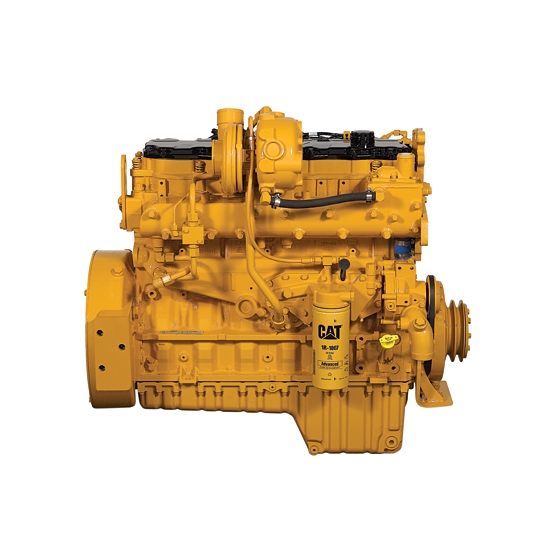

C9 ACERT™ Dry Manifold Engine

General Specifications

- Maximum Rating

- 375BHP

- Displacement

- 538in³

- Minimum Rating

- 205BHP

- Governor and Protection

- Electronic (ADEM™ A3)

- Aspiration

- Turbocharged-Aftercooled

- Flywheel and Flywheel Housing

- SAE 1 or 2

- Flywheel Teeth

- 113 (SAE 1), 134 (SAE 2)

- Rotation from Flywheel End

- Counterclockwise

- Stroke

- 5.8in

- Bore

- 4.41in

Emissions

- Emissions

- EPA and CARB Non-Road Tier 3, EU Stage IIIA, IMO Tier II

Dimensions

- Length

- 43in

- Width

- 32.6in

- Height

- 40.3in

- Weight

- 1578lb

Capacity for Liquids

- Lube Oil System - Refill

- 8gal (US)

- Cooling System

- 3.7gal (US)

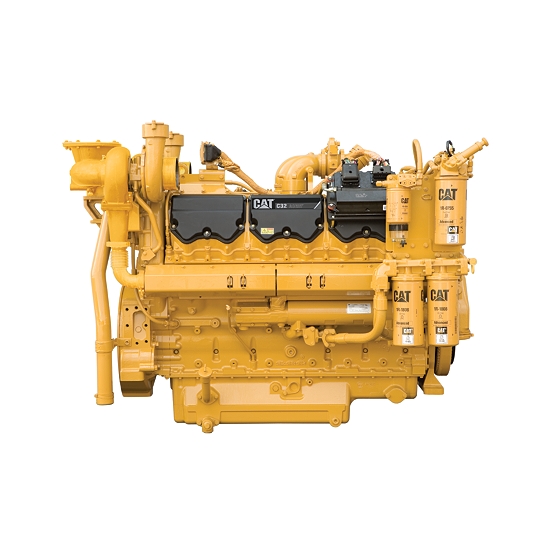

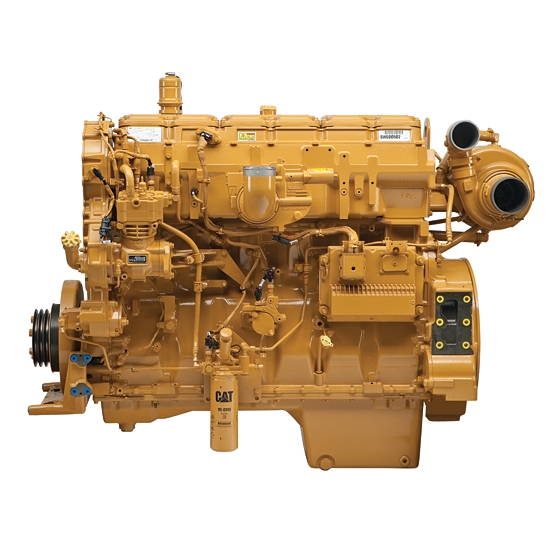

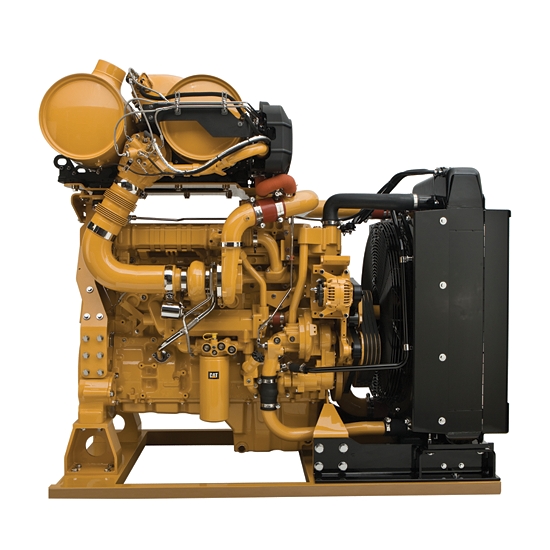

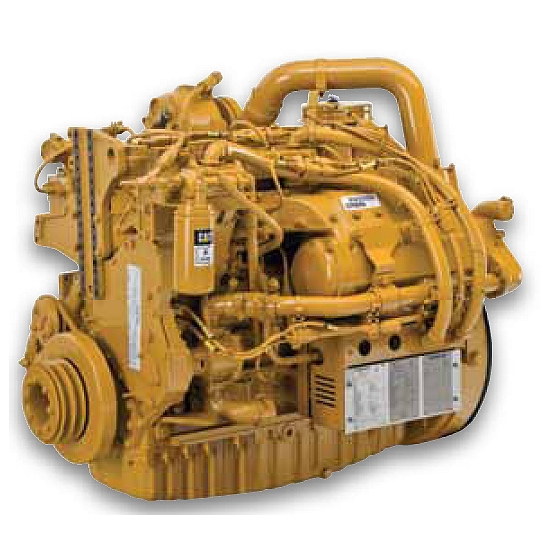

Custom Packaging

For any petroleum application, trust Caterpillar to meet your project needs with custom factory generator sets and mechanical packages. Cat engines, generators, controls, radiators, and transmissions can be custom designed and matched in collaboration with our local dealers to create unique solutions. Custom packages are globally supported and are covered by a one year warranty after startup.

Custom Packaging

For any petroleum application, trust Caterpillar to meet your project needs with custom factory generator sets and mechanical packages. Cat engines, generators, controls, radiators, and transmissions can be custom designed and matched in collaboration with our local dealers to create unique solutions. Custom packages are globally supported and are covered by a one year warranty after startup.

Full Range of Attachments

Large variety of factory installed engine attachments reduces packaging time

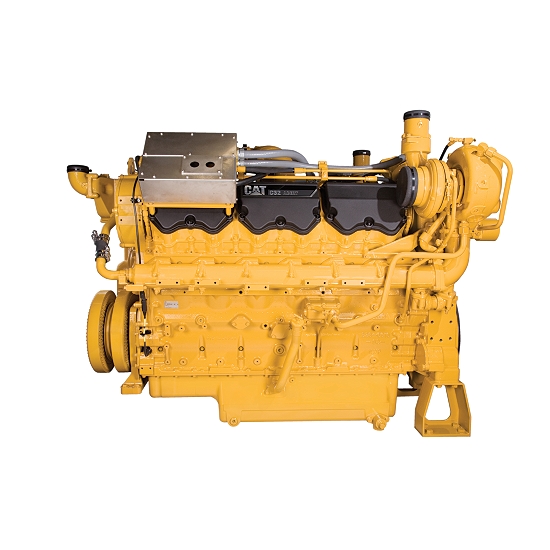

Testing

Every engine is full-load tested to ensure proper engine performance.

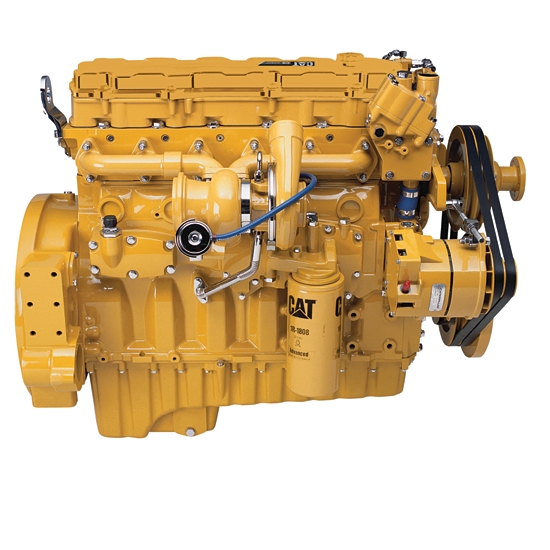

Product Support Offered Through Global Cat Dealer

- More than 2,200 dealer outlets - Cat factory-trained dealer technicians service every aspect of your petroleum engine - Cat parts and labor warranty - Preventive maintenance agreements available for repairbefore-failure options - S•O•SSM program matches your oil and coolant samples against Caterpillar set standards to determine: - Internal engine component condition - Presence of unwanted fluids - Presence of combustion by-products - Site-specific oil change interval

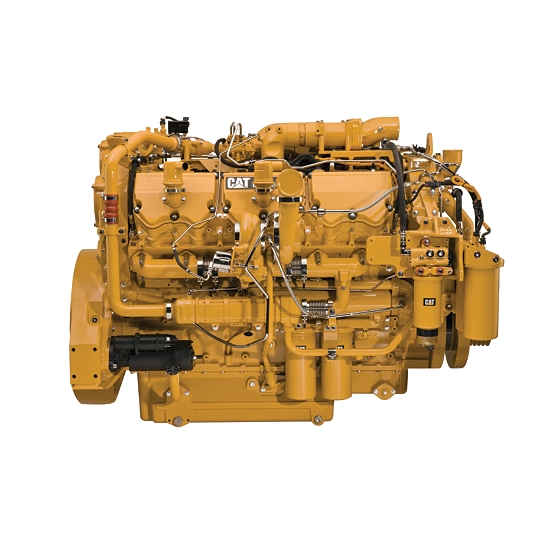

Over 80 Years of Engine Manufacturing Experience

Ownership of these manufacturing processes enables Caterpillar to produce high quality, dependable products.

Over 80 Years of Engine Manufacturing Experience

Ownership of these manufacturing processes enables Caterpillar to produce high quality, dependable products.

Web Site

For all your petroleum power requirements, visit www.cat.com/oilandgas.