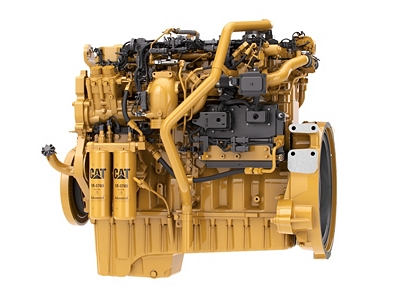

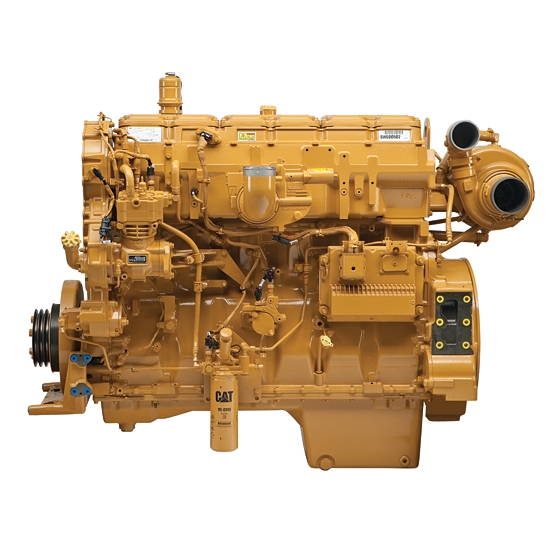

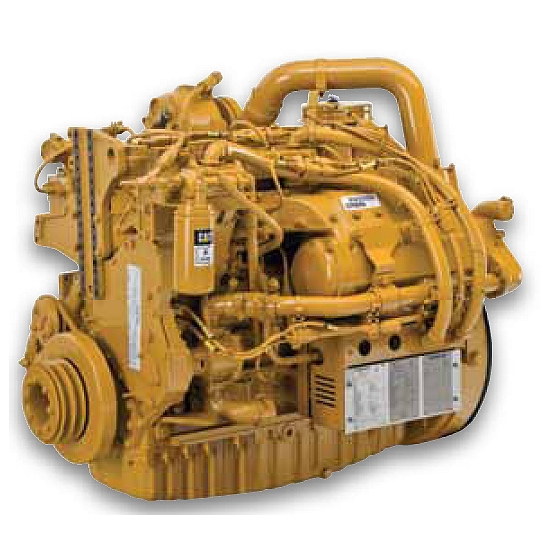

C9.3 ACERT™ Tier 4 Final Engine

General Specifications

- Maximum Rating

- 455BHP

- Displacement

- 567.5in³

- Minimum Rating

- 335BHP

- Aspiration

- Turbocharged-Aftercooled

- Flywheel and Flywheel Housing

- SAE 1 or 2

- Flywheel Teeth

- 113 (SAE 1), 138 (SAE 2)

- Stroke

- 5.9in

- Bore

- 4.5in

Emissions

- Emissions

- EPA Tier 4 Final and EU Stage IV

Dimensions

- Length

- 44.3in

- Width

- 31.1in

- Height

- 41.9in

- Weight

- 1907lb

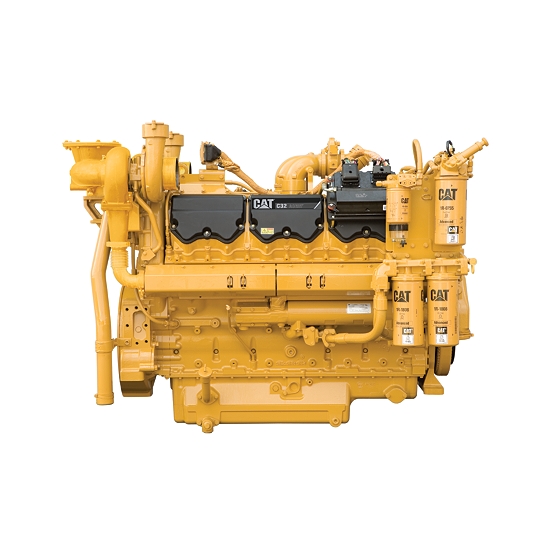

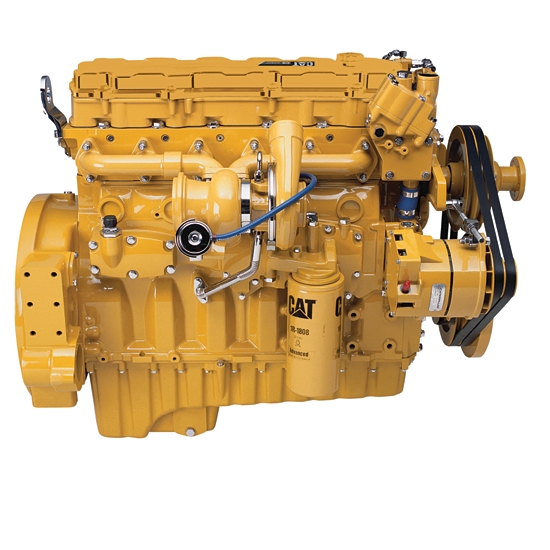

Reliable, Quiet and Durable Power

World-class manufacturing capability and processes coupled with proven core engine designs assure reliability, quiet operation, and many hours of productive life.

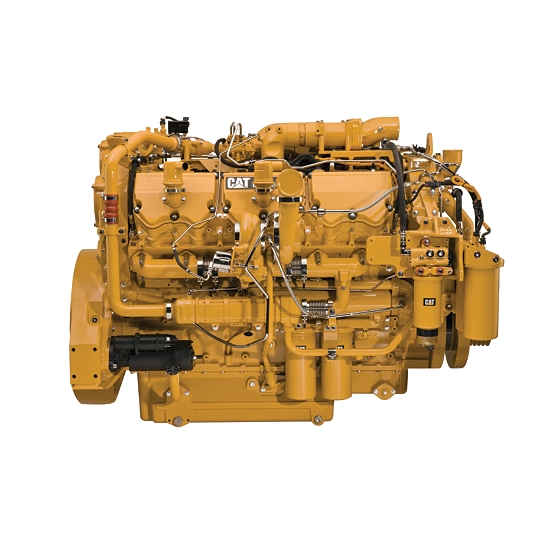

High Performance

Simple and efficient turbocharger with balance valve provides optimal air management and improved fuel efficiency.

Fuel Efficiency

Fuel consumption optimized to match operating cycles of a wide range of equipment and applications while maintaining low operating costs.

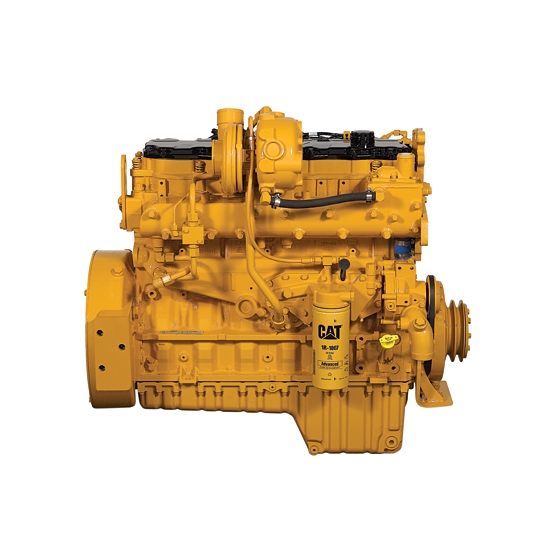

Fuel & Oil

Tier 4 Final, Stage IV engines require Ultra Low Sulfur Diesel (ULSD) fuel containing a maximum of 15 ppm sulfur, and new oil formulations to support the new technology. Cat® engines are designed to accommodate B20 biofuel. Your Cat dealer can provide more information regarding fuel and oil.

Broad Application Range

Industry-leading range of factory configurable ratings and options for agricultural, materials-handling, construction, mining, forestry, waste, and other industrial applications.

Package Size

Exceptional power density enables standardization across numerous applications. Multiple installation options minimize total package size. Ideal for equipment with narrow engine compartments.

Package Size

Exceptional power density enables standardization across numerous applications. Multiple installation options minimize total package size. Ideal for equipment with narrow engine compartments.

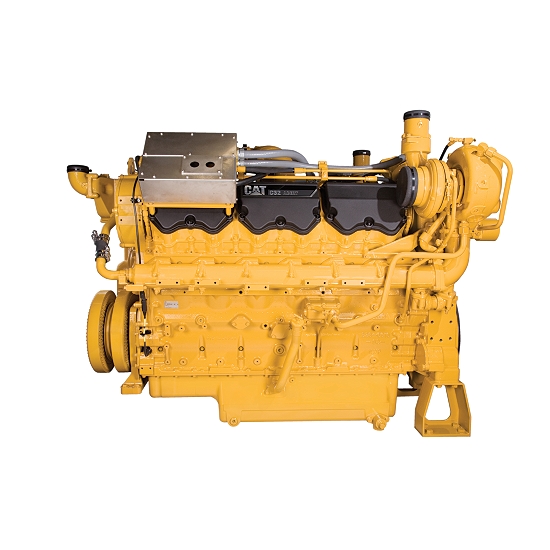

Low-Cost Maintenance

Worldwide service delivers ease of maintenance and simplifies the servicing routine. Minimum 5000-hour diesel particulate filter (DPF) ash service interval enables low-cost maintenance. Capable of optimal oil change intervals of up to 500 hours, depending on rating, application, operating conditions, and maintenance practices. Engine is designed for a B10 life of up to 10,000 hours. The S•O•SSM program is available from your Cat dealer to determine oil change intervals and provide optimal performance.

Quality

Every Cat engine is manufactured to stringent standards in order to assure customer satisfaction.

World-class Product Support Offered Through

• Scheduled maintenance, including S•O•S SM sample • Customer Support Agreements (CSA) • Caterpillar Extended Service Coverage (ESC) • Superior dealer service network • Extended dealer service network through the Cat Industrial Service Distributor (ISD) program