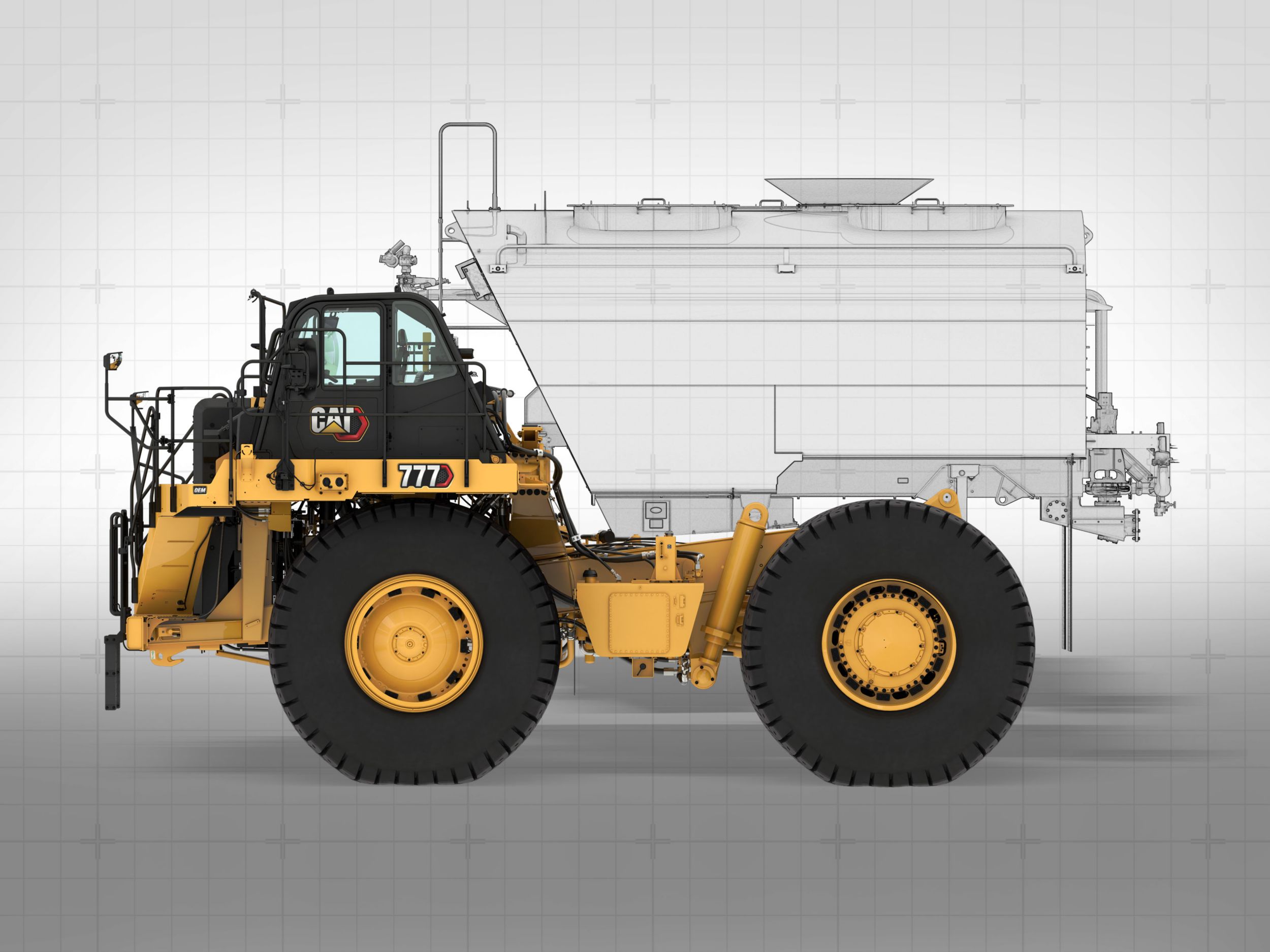

777 Off-Highway Truck bare chassis

Caterpillar offers partial machines and systems, working with Cat dealers and Original Equipment Manufacturers (OEMs) to provide specialty machines for specific applications. Bare chassis trucks (WTR models) can be ordered ...

Weights

- LRC Bare Chassis Weight without Hoist

- 111505lb

- LRC Bare Chassis Weight with Hoist

- 114067lb

- LRC Gross Vehicle Weight (Target) without Hoist

- 363000lb

- LRC Gross Vehicle Weight (Target) with Hoist

- 363000lb

- HRC Bare Chassis Weight without Hoist

- 112656lb

- HRC Bare Chassis Weight with Hoist

- 115218lb

- HRC Gross Vehicle Weight (Target) without Hoist

- 363000lb

- HRC Gross Vehicle Weight (Target) with Hoist

- 363000lb

- Note

- LRC model is offered for lesser regulated countries. HRC model is offered for highly regulated countries. Available as Tier 4 Final/Stage V equivalent, Tier 3/Stage IIIA equivalent, or Tier 2/Stage II equivalent emission standards.

ROPS

- Tractor ROPS

- 133082lb

Operating Specifications

- Nominal Water Tank Capacity

- 20000gal (US)

Engine

- Engine Model

- Cat® C32B

- Gross Power - SAE J1995

- 1025hp

- Rated Net Power - SAE J1349

- 916hp

- Bore

- 5.7in

- Stroke

- 6.4in

- Displacement

- 1959in³

- Rated Engine Speed

- 1800r/min

- Number of Cylinders

- 12

- Note

- Net Power advertised is the power available at the flywheel when the engine is equipped with air intake system, exhaust system, and alternator. U.S. EPA Tier 4 Final / EU Stage V available for applicable markets.

Transmission

- Forward - 1

- 6.6mile/h

- Forward - 2

- 9.1mile/h

- Forward - 3

- 11.9mile/h

- Forward - 4

- 16.6mile/h

- Forward - 5

- 22.5mile/h

- Forward - 6

- 30.2mile/h

- Forward - 7

- 40.9mile/h

- Reverse

- 7.5mile/h

Brakes

- Brake Surface - Front

- 6331in²

- Brake Surface - Rear

- 15828in²

Service Refill Capacities

- Fuel Tank Capacity

- 300gal (US)

- Cooling System

- 63.4gal (US)

- Crankcase

- 28.7gal (US)

- Steering System - Including Tank

- 14.1gal (US)

- Brake/Hoist Hydraulic Tank

- 117gal (US)

- Brake Hoist System

- 85gal (US)

- Torque Converter - Transmission System

- 36.5gal (US)

Steering

- Steering Standards

- ISO 5010:2007

- Steer Angle

- 30.5°

- Turning Diameter

- 83ft

- Turning Circle - Clearance Diameter

- 93ft

Tractor ROPS Rating

- Cat® Off-Highway Truck Bare Chassis ROPS is certified to ISO 3471 Tractor criteria, to provide a higher level of protection for towing applications.

Water Truck Applications

- Cat Off-Highway Truck Bare Chassis are rugged and reliable platforms for water truck applications in both mining and construction projects.

- Using an off-highway truck bare chassis provides a solution that is ideal for dust suppression, road construction, fire protection, and other applications.

- Caterpillar works with OEMs worldwide to match the appropriate bare chassis machine to the water truck application, all through your local Cat dealer, to provide the best solution for your business.

Service Truck Applications

- Cat Off-Highway Truck Bare Chassis are rugged and reliable platforms for service truck applications in both mining and construction projects.

- Using an off-highway truck bare chassis provides a solution that is ideal for delivering fuel and preventive maintenance lubrication to your site's machine fleet.

- Caterpillar works with OEMs worldwide to match the appropriate bare chassis machine to the service truck application, all through your local Cat dealer, to provide the best solution for your business.

Tow Applications

- Cat Off-Highway Truck Bare Chassis are rugged and reliable platforms for tow applications.

- Using an off-highway truck bare chassis provides a solution that is ideal for equipment trailers and bottom dump trailers.

- Caterpillar works with OEMs worldwide to match the appropriate bare chassis machine to the tow application, all through your local Cat dealer, to provide the best solution for your business.