318F L Hydraulic Excavator

The Cat® 318F L is a perfect choice for customers who value versatility, reliability, durability, and maximum efficiency.

Engine

- Net Power - ISO 9249

- 117HP

- Engine Model

- C4.4

- Engine Power - ISO 14396

- 122HP

- Bore

- 4.13in

- Stroke

- 5in

- Displacement

- 269in³

Weights

- Operating Weight

- 42340lb

Working Ranges & Forces

- Maximum Digging Depth

- 20ft

- Boom

- Reach 5.1 m (16'9")

- Stick

- R2.9 m (9'6")

- Bucket

- .91 m³ (1.19 yd³)

- Maximum Reach at Ground Level

- 28.83ft

- Maximum Cutting Height

- 29.25ft

- Maximum Loading Height

- 20.58ft

- Minimum Loading Height

- 7.42ft

- Maximum Depth Cut for 2440 mm (8 ft) Level Bottom

- 20.1ft

- Maximum Vertical Wall Digging Depth

- 16.17ft

- Bucket Digging Force - ISO

- 27651lbf

- Stick Digging Force - ISO

- 17984lbf

Hydraulic System

- Main System - Maximum Flow

- 300 l/min (79 gal/min)

- Maximum Pressure - Equipment

- 5076psi

- Maximum Pressure - Swing

- 3626psi

- Maximum Pressure - Travel

- 5076psi

Swing Mechanism

- Swing Speed

- 8.5r/min

- Maximum Swing Torque

- 37394ft·lbf

Service Refill Capacities

- Fuel Tank Capacity

- 76.61gal (US)

- Cooling System

- 6.9gal (US)

- Engine Oil

- 3.57gal (US)

- Swing Drive

- 2.11gal (US)

- Final Drive - Each

- 2.11gal (US)

- Hydraulic System - Including Tank

- 31.96gal (US)

- Hydraulic Tank

- 28gal (US)

- DEF Tank

- 5.4gal (US)

Dimensions

- Boom

- Reach 5.1 m (16'9")

- Stick

- R2.9 m (9'6")

- Bucket

- .91 m³ (1.19 yd³)

- Shipping Height - Top of Cab

- 10.17ft

- Shipping Length

- 28.17ft

- Tail Swing Radius

- 8.25ft

- Counterweight Clearance

- 3.33ft

- Ground Clearance

- 1.42ft

- Track Length

- 13.33ft

- Length to Center of Rollers

- 10.75ft

- Track Gauge

- 6.5ft

- Transport Width

- 8.83ft

EFFICIENCY AND PRODUCTIVITY

- The C4.4 engine meets U.S. EPA Tier 4 Final/EU Stage IV emission standards. It is powerful and efficient, and it can run on biodiesel up to B20.

- Advanced control automatically manages pump and engine speed for maximum efficiency.

- Two power modes, high power and eco mode, help you actively manage fuel consumption.

- Engine idle shutdown saves fuel, and extends service intervals.

PURPOSE-BUILT CAT ATTACHMENTS

- Site prep and finishing work are quick and easy with a wide range of Cat work tools.

- Utility work is fast and flawless with a Cat bucket and compactor.

- A coupler lets you swap between attachments in seconds without leaving the cab.

- See the whole money-making attachment line for your machine at www.cat.com/attachments.

DESIGNED FOR OPERATORS

- The roll-over protective structure (ROPS) certified cab is quiet and comfortable.

- Automatic climate control helps maintain consistent cab temperature.

- Joystick consoles and armrests are adjustable.

- Seats are adjustable and feature air suspension (Europe, Australia, New Zealand and Pacific Islands) with an optional heater.

- The LCD monitor is easy to navigate and programmable in 42 languages.

REDUCED MAINTENANCE TIME

- Many routine service and maintenance points can be accessed from ground level reducing the time taken to check and service your machine.

- Wide service doors make for easy access.

- Filters are grouped to reduce service time.

- The cooling package is designed to prevent plugging, make blowing off debris easy.

TECHNOLOGY THAT GETS WORK DONE

- Cat technology improves job site efficiency.

- Optional Cat Grade Control helps you create a level base and precise slope with ease.

- Product Link™/VisionLink® connects owners to the machine, providing access to location, hours, fuel consumption, idle time, events, and diagnostic codes.

BUILT TO PERFORM

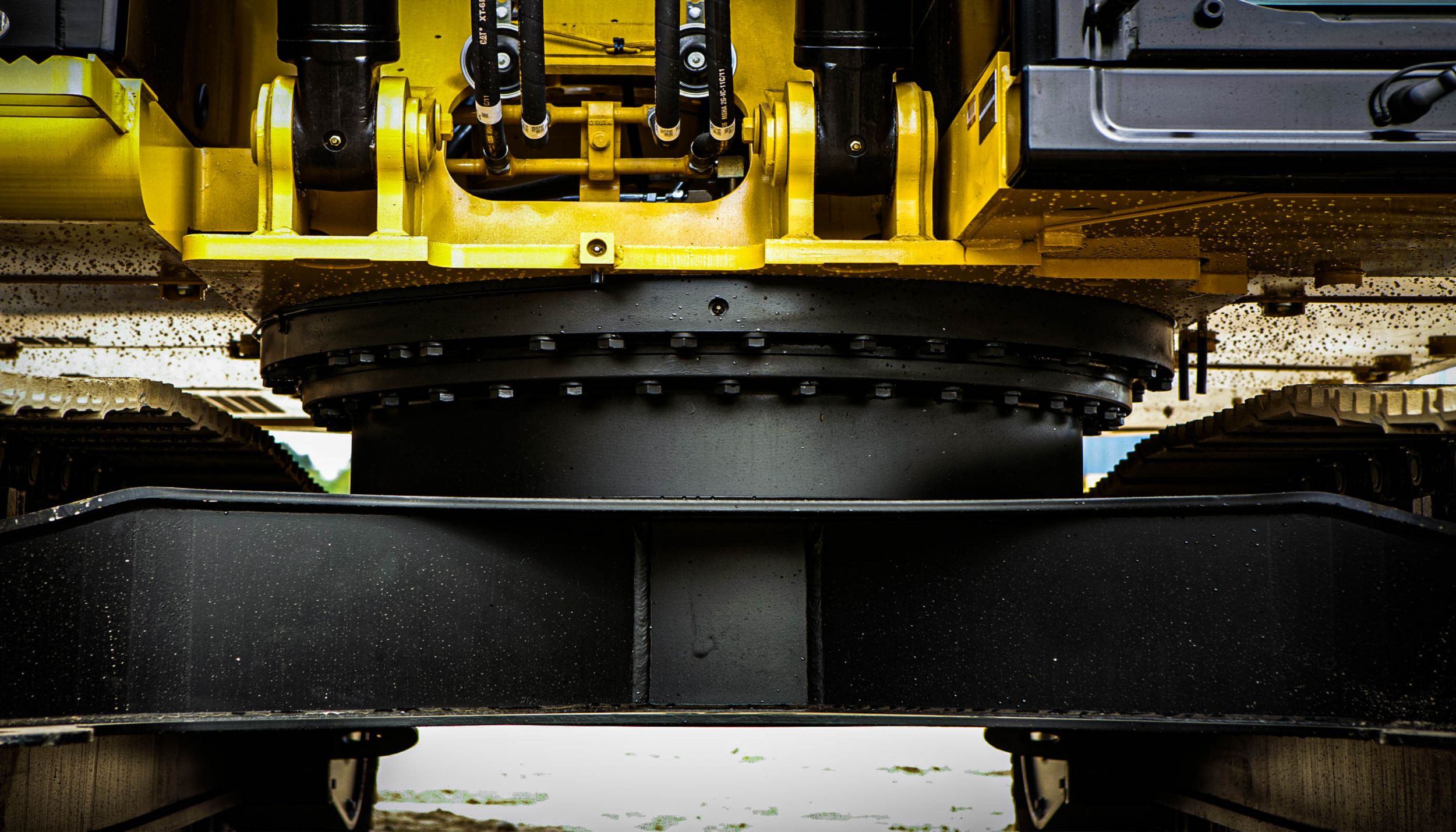

- The large swing bearing is secured with elongated bolts to help handle the most swing-intensive work.

- Robot welded, Caterpillar designed boom and sticks are built for long service.

- Greased track link between pins and bushings increases undercarriage life and reduces noise.

BUILT-IN SAFETY FEATURES

- The hydraulic activation lever locks out all hydraulic functions.

- Handrails, anti-skid plating, and countersunk bolts reduce slipping and tripping.

- A ground-level engine shutoff switch shuts down the engine in case of emergency.

- Standard rearview camera and mirrors enhance visibility.

- The side-view camera enhances visibility on the boom side of the machine to help make operators more effective and efficient (Europe only).