Engine Specifications

- Maximum Rating

- 1380BHP

- Rated Speed

- 1400rpm

- Emissions

- Rich Burn: EPA NSPS Site Compliant Capable with Caterpillar Supplied AFRC and Customer Supplied Aftertreatment

- Minimum Rating

- 660BHP

- Bore

- 6.7in

- Stroke

- 6in

- Displacement

- 69in³

- Length

- 143.8in

- Width

- 77.7in

- Height

- 89.9in

- Weight - Dry

- 20352lb

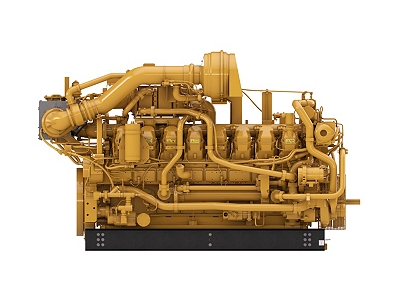

Engine Design

- Engine design built on G3500 proven reliability and durability - Ability to burn a wide spectrum of gaseous fuels - Robust diesel strength design prolongs life and lowers owning and operating costs - Broad operating speed range at lower site air densities (high altitude/hot ambient temperatures) - Higher power density improves fleet management - Quality engine diagnostics - Detonation-sensitive timing control for individual cylinders

Emissions

When configured with customer-supplied air fuel ratio control and three-way catalyst, the engine is capable of meeting NSPS and non-attainment area emissions levels.

Advanced Digital Engine Management

ADEM A4 engine management system integrates speed control, air/fuel ratio control, and ignition/detonation controls into a complete engine management system. ADEM A4 has improved: user interface, display system, shutdown controls, and system diagnostics.

Full Range of Attachments

Large variety of factory-installed engine attachments reduces packaging time

Testing

Every engine is full-load tested to ensure proper engine performance.

Gas Engine Rating Pro

GERP is a web-based program designed to provide site performance capabilities for Cat® natural gas engines for the gas compression industry. GERP provides engine data for your site's altitude, ambient temperature, fuel, engine coolant heat rejection, performance data, installation drawings, spec sheets, and pump curves.

Product Support Offered Through Global Cat Dealer

- More than 2,200 dealer outlets - Cat factory-trained dealer technicians service every aspect of your petroleum engine - Cat parts and labor warranty - Preventive maintenance agreements available for repair-before-failure options - S•O•SSM program matches your oil and coolant samples against Caterpillar set standards to determine: - Internal engine component condition - Presence of unwanted fluids - Presence of combustion by-products - Site-specific oil change interval

Over 80 Years of Engine Manufacturing Experience

Over 60 years of natural gas engine production. Ownership of these manufacturing processes enables Caterpillar to produce high quality, dependable products. - Cast engine blocks, heads, cylinder liners, and flywheel housings - Machine critical components - Assemble complete engine

Web Site

For all your Oil & Gas power requirements, visit www.cat.com/oilandgas