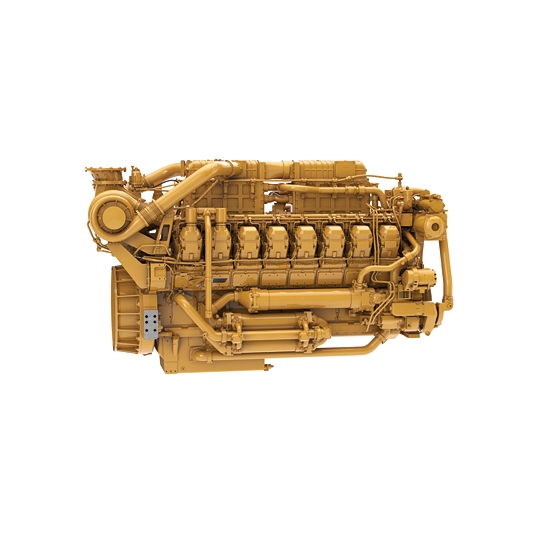

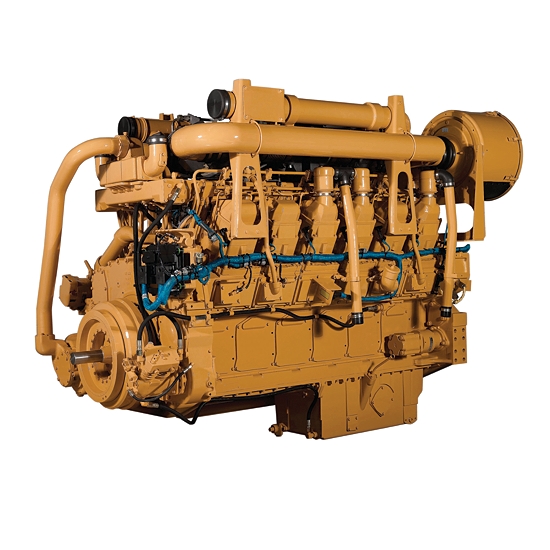

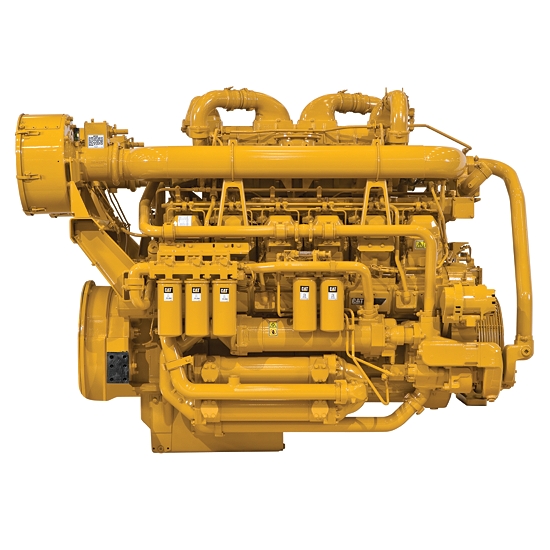

3512C (HD) Offshore Well Stimulation Engine

The 3512C (HD) offshore engine for well stimulation operations was specifically developed to operate in harsh environments offshore while meeting the highest standards in performance, durability, reliability, and emissions. Cat

...The 3512C (HD) offshore engine for well stimulation operations was specifically developed to operate in harsh environments offshore while meeting the highest standards in performance, durability, reliability, and emissions. Cat engines are backed by the worldwide network of Cat dealers ready to support your operation with technical support, service, parts, and warranty. 3512C (HD) offshore engines, with ratings: 1678-1864 bkW (2250-2500 bhp) @ 1900 rpm meet IMO Tier II and U.S. EPA Marine Tier 2 emission standards.

General Specifications

- Maximum Rating

-

2500BHP

- Displacement

-

58.9in³

- Minimum Rating

-

2150BHP

- Aspiration

-

Turbocharged-Aftercooled

- Flywheel and Flywheel Housing

-

SAE No. 0

- Flywheel Teeth

-

151

- Stroke

-

8.5in

- Bore

-

6.7in

Emissions

- Emissions

-

IMO Tier II and EPA Marine Tier 2

Dimensions

- Length

-

113.8in

- Width

-

64.2in

- Height

-

86.1in

- Weight

-

14145lb

Cooling System

Separate Circuit Aftercooler (SCAC)

Engine-Mounted Transmission Oil Cooler —

Integration with engine cooling system allows ease of installation and a tighter overall engine package

Advanced Digital Engine Management

ADEM A3 engine management system integrates speed control, air/fuel ratio control and ignition/detonation controls into a complete engine management system with integrated digital ignition, engine protection and monitoring

Custom Packaging

For any petroleum application, trust Caterpillar to meet your project needs with custom factory generator sets and mechanical packages. Cat engines, generators, controls, radiators, and transmissions can be custom designed and matched in collaboration with our local dealers to create unique solutions. Custom packages are globally supported and are covered by a one year warranty after startup.

Full Range of Attachments

Large variety of factory-installed engine attachments reduces packaging time

Testing

Every engine is full-load tested to ensure proper engine performance

Product Support Offered Through Global Cat Dealer

- More than 2,200 dealer outlets - Cat factory-trained dealer technicians service every aspect of your petroleum engine - Cat parts and labor warranty - Preventive maintenance agreements available for repairbefore-failure options - S•O•SSM program matches your oil and coolant samples against Caterpillar set standards to determine: • Internal engine component condition • Presence of unwanted fluids • Presence of combustion by-products • Site-specific oil change interval

Over 80 Years of Engine Manufacturing Experience

- Ownership of these manufacturing processes enables Caterpillar to produce high quality, dependable products. • Cast engine blocks, heads, cylinder liners, front and flywheel housings • Machine critical components • Assemble complete engine

Website

For all your petroleum power requirements, visit www.cat.com/oilandgas

Standard Equipment:

- Air Inlet System

-

- Heavy-duty air cleaners (dual element/service indicator)

- Four center-mounted turbochargers

- Control System

-

- Cat® ADEM A3 ECU — LH

- With electronic fuel injector fuel system (10 amp DC power required to drive electronic engine control module)

- Cooling System

-

- Separate Circuit SCAC system

- Torque converter connections

- Thermostats and housing, jacket and separate circuit water pump, gear-driven centrifugal

- Exhaust System

-

- Land well service engine

- Exhaust manifold, dry, slip joint with stainless steel wire seal

- Four turbochargers with watercooled bearings (center mounted)

- Exhaust outlet, dual 203 mm (8 in) round flange

- Flywheel And Flywheel Housings

-

- Flywheel, SAE No. 0, 151 teeth

- Flywheel housing, SAE No. 0

- Fuel System

-

- Primary fuel filter

- Fuel priming pump

- Fuel filter — RH spin-on type

- Fuel transfer pump

- Electronically controlled unit injectors

- Instrumentation

-

- No standard instrumentation

- Optional, remote instrumentation available

- Service meter

- Lube System

-

- Crankcase breather — top mounted

- Oil cooler

- Oil filler and dipstick — LH

- Oil pump

- Oil filter — RH spin-on type

- Rear sump oil pan — 250-hour change interval

- Oil pan drain valve — 1" NPT female connection

- Fumes disposal

- Scavenger pump

- Power Take-offs

-

- Accessory drive — lower LH

- Front housing — two-sided

- Protection System

-

- ADEM A3 ECU system to provide customer programmable engine deration strategies to protect against adverse operating conditions

- Emergency stop logic inputs provided at 40-pin customer interface connection

- Dual air inlet shutoff

- Oil pressure monitor

- General

-

- General

- Vibration damper and guard

- Lifting eyes

Optional Equipment:

- Control System

-

- Local speed throttle control

- Throttle position sensors

- Governor conversion

- Cooling System

-

- Coolant regulator conversion

- Water level switch gauge

- Coolant level sensors and coolant conditioner

- Exhaust System

-

- Flexible exhaust fitting

- Elbows, flange, exhaust adapters

- Manifold and mufflers

- Fuel Systems

-

- Flexible fuel lines

- Water/fuel separator

- Fuel level switch

- Instrumentation

-

- Remote panel display and remote cylinder temperature display

- Gauges and instrument panels

- Lube System

-

- Oil pans and filters

- Deep sump oil pan and front sump pan

- Power Take-offs

-

- Front crankshaft adapter

- Flywheel stub shaft

- Starting System

-

- Air starting motors

- Electric starting motors

- Hydraulic starter

- Ether starting aids

- Battery sets — 24V

- Battery cable and battery rack