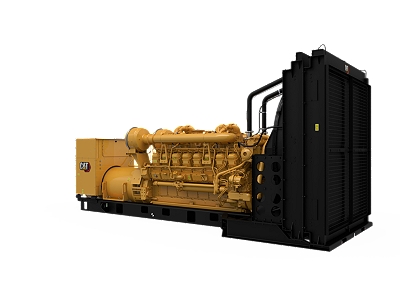

3516B Generator Set

Caterpillar is leading the power generation marketplace with Power Solutions engineered to deliver unmatched flexibility, expandability, reliability, and cost-effectiveness.

Generator Set Specifications

- Standby Rating

- 2250 ekW

- Prime Power Rating

- 1825 ekW

- Emissions/Fuel Strategy

- Low Fuel, Low Emissions

- Voltage

- 380 to 13800 Volts

- Frequency

- 60 Hz

- Speed

- 1800 rpm

- Duty Cycle

- Standby, Mission Critical, Prime, Continuous

- Maximum Rating

- 2250 ekW

- Minimum Rating

- 1640 ekW

Engine Specifications

- Engine Model

- 3516B TA, V-16, 4-Stroke Water-Cooled Diesel

- Bore

- 6.69in

- Stroke

- 7.48in

- Displacement

- 4210.64in

- Compression Ratio

- 14.0:1 Std 15.5:1 HD

- Aspiration

- TA

- Fuel System

- Electronic unit injection

- Governor Type

- Adem™3

Generator Set Dimensions

- Length - Minimum

- 241.8in

- Length - Maximum

- 269.9in

- Width - Minimum

- 90in

- Width - Maximum

- 101.9in

- Height - Minimum

- 98.2in

- Height - Maximum

- 120.1in

- Dry Weight - Genset (minimum)

- 31270lb

- Dry Weight - Genset (maximum)

- 34420lb