D7 Dozer

Engine

- Engine Model

- Cat C9.3B

- Power - Net

- 265hp

- Net Power - Rated - ISO 9249/SAE J1349

- 265hp

- Net Power (Rated) - ISO 9249 (DIN)

- 268mhp

- Emissions

- U.S. EPA Tier 4 Final/EU Stage V/Japan 2014/Korea Stage V/China Nonroad Stage IV

- Note (1)

- Net power at 2,200 rpm. Net power advertised is the power available at the engine flywheel when the engine is equipped with a fan, air cleaner, clean emissions module and alternator. Advertised power is tested per the specified standard in effect at the t

- Note (2)

- Cat diesel engines are required to use ULSD (ultra-low sulfur diesel fuel with 15 ppm of sulfur or less) or ULSD blended with the following lower-carbon intensity fuels up to: 20% biodiesel FAME (fatty acid methyl ester) ** or 100% renewable diesel, HVO (

- Note (3)

- Basic machine specs provided below. For complete specifications and dimensions by configuration, blade and track shoe offerings and more, please visit the product download section to view the full Technical Specifications document.

- Note (4)

- Machine Build Number 17A

Weights

- Operating Weight

- 65644lb

- Note (1)

- Standard SU operating weight includes ripper with three shanks adding approximately 2993 kg/6596 lbs. LGP S operating weight with drawbar.

Transmission

- Powertrain

- Fully Automatic 4-Speed

Service Refill Capacities

- Fuel Tank

- 123gal (US)

- DEF Tank

- 12gal (US)

Standard SU

- Operating Weight

- 65644lb

- Ground Pressure

- 10psi

- Width of Standard Shoe

- 24in

- Blade

- Semi-Universal (SU)

- Blade Capacity

- 10yd³

LGP S

- Operating Weight

- 63220lb

- Ground Pressure

- 6psi

- Width of Standard Shoe

- 36in

- Blade

- Straight (S)

- Blade Capacity

- 8yd³

Waste Handler

- Operating Weight

- 62035lb

- Ground Pressure

- 10psi

- Width of Standard Shoe

- 24in

- Blade

- Universal Landfill (U)

- Blade Capacity

- 22yd³

Sustainability

- Recyclability

- 98%

Air Conditioning System

- Air Conditioning

- The air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a (Global Warming Potential = 1430). The system contains 1.36 kg of refrigerant which has a CO2 equivalent of 1.946 metric tonnes.

Dimensions

- Note (2)

- Configurations and features may vary by region. Please consult your Cat dealer for availability in your area.

NEXT GENERATION PERFORMANCE

- Harness 6% more weight and 12% more horsepower than D7E to take on a wide range of dozing and grading tasks.

- Move up to 8% more material per hour.

- Like D6 and D8, fully automatic 4-speed powershift transmission continuously adjusts for maximum efficiency and power to the ground without added operator input.

- SU and S blades are 10% larger to help you get jobs done in fewer passes.

- Optional FirstCut™ cutting edges for SU blades increase blade payload by up to 35% compared to standard cutting edges.

- Elevated sprocket gives you better ride and balance, plus more penetration force.

- Outfit your dozer from the factory to take on the challenges of waste handling, land clearing, stockpile work, dredging and more.

All comparisons to D7E.

OPERATOR HELPERS

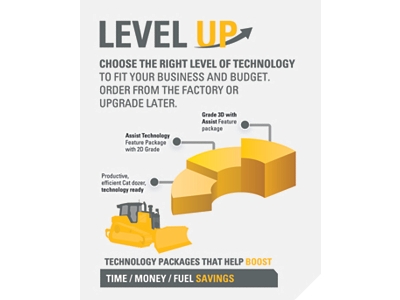

- Cat Grade with Slope Assist™ automatically maintains pre-established blade position without a GNSS/GPS signal – no additional hardware or software needed. For machines with 3D, operators can easily switch back and forth from full 3D automatics to Slope Assist.

- Steer Assist automates track and blade tilt steering. Helps reduce operator fatigue by automatically maintaining straight travel with light loads or heavy loads on flat ground and side slopes. Helps reduce steering inputs up to 75%. No GNSS/GPS required.

- Stable Blade works seamlessly with operator inputs to help produce a smoother surface when operating manually.

- Blade Load Monitor gives you real-time feedback on current load versus the optimal blade load based on your ground conditions. Actively monitors machine load and track slip to help you reach optimal pushing capacity.*

- Traction Control automatically reduces track slip to save you time, fuel and track wear.*

- AutoCarry automates blade lift to help you maintain consistent blade load and reduce track slip.*

- Slope Indicate is included in the main machine display and shows side slope and uphill/downhill grades to help operators with slope work.

- Attachment Ready Option (ARO) provides wiring and mounting provisions for dealer installation of Grade with 3D, Accugrade, UTS, or other grade control systems.

Assist features help make work easier, especially for less experienced operators. Some blade and steering functions are automated so newer operators can work at productivity levels closer to their veteran counterparts. Seasoned operators can enjoy reduced effort and fatigue, along with faster, more accurate results.

*Feature not operational indoors or in areas where a GNSS/GPS signal is not available.

TOP GRADES

- Factory integrated Cat Grade with 3D uses GNSS/GPS to control the blade so you can get to design plan faster.

- Cat Grade with 3D has no masts – low profile antennas are integrated into the cab roof and GNSS/GPS receivers are mounted inside the cab for better protection.

- Automatically follow guidance lines from design plans with Steer Assist 3D. Stay on curb lines, centerlines, bottom of slope, etc., without operator effort. Track steering is used under light loads and blade tilt steering may be added under heavy loads.

- Grade operator interface is intuitive and easier to use: 10-inch (254 mm) touchscreen, Android OS platform, operates like a smart phone.

- All Cat Grade systems are compatible with radios and base stations from Trimble, Topcon, and Leica.

- Already invested in a grade infrastructure? You can install grade systems from Trimble, Topcon, and Leica onto the machine.

- The cab is Third Party Grade Control Ready, equipped with CAN interface, harness pass throughs and mounting features to make it easier to install the grade control system of your choice.

PROVEN ADVANTAGE

Cat Assist and Grade technologies work in the background to help dozer operators of varied skill levels and are especially beneficial to less experienced operators. To demonstrate just how much these built-in technology features help, Caterpillar put them to the test. Two novice operators and two expert operators took on slot dozing, truck dump spreading/grading in sand, and side slope work. Each operator completed three runs of each task – one in manual, one using Assist technology features, and one using Assist plus Cat Grade with 3D. The team measured productivity*, efficiency**, completion time, final surface quality, and operator inputs.

Slot Dozing

• Productivity and Efficiency – Novice operators went from 9% lower productivity and efficiency than the experts in manual to matching the experts when using Assist.

Truck Dump Spreading/Grading in Sand

• Completion Time – Novice operators took 49% more time than the experts in manual and narrowed the gap to 17% using Assist and to 9% by adding Grade.

• Blade Inputs – Novice operator blade inputs were reduced 45% with Assist, and 55% with Assist plus Grade. Expert operator blade inputs were reduced 32% with Assist, and 53% with Assist plus Grade.

• Surface Quality – Novice operator surface quality improved up to 51% using technology while expert operator surface quality improved up to 27% using technology. Novice operators using technology produced similar surface quality to the expert operators in manual.

Side Slope/Steer Assist

• Steering Inputs – Novice and expert operator steering inputs reduced by 75% in forward and by 67% combining forward and reverse.

*Material moved per hour

**Material moved per unit of fuel/Diesel Exhaust Fluid (DEF)

Study conducted by Caterpillar, August 2022

COMFORT AND VISIBILITY

- Common cab with D5 and D6, for a whole new standard in comfort and productivity.

- Easy-to-use 10-inch (254 mm) touchscreen main display.

- Standard High Definition rearview camera shows prominently in the main display.

- Key Features Help, built into the display, gives you an overview of machine and technology features and helpful operating tips.

- Wide air suspension seat has multiple adjustments for personalized comfort.

- Ample storage spaces throughout the cab.

REMOTE CONTROL READY

- Cab is Remote Control Ready from the factory with external connector for dealer installation of the Cat Command system.

- Cat Command remote control technology provides full dozer maneuverability from a safe distance when working in hazardous environments.

- Command offers the choice of line-of-sight consoles or long-distance operator stations (non-line-of-sight).

- Take advantage of the dozer’s Grade and Assist features while out of the cab using the Command Station or Console.*

*Not all technology features are available on the Command Console. Please consult your Cat dealer for feature availability by dozer model.

BUILT-IN DURABILITY

- Elevated sprocket protects major components from shock loads.

- Heavier frame and structures for added durability.

- Cat C9.3B engine eliminates Exhaust Gas Recirculation (EGR) system for greater reliability; Simplified with a single engine Electronic Control Module (ECM).

- Redesigned fuel system provides greater reliability and more accurate fuel delivery.

- Heavy Duty Extended Life undercarriage – HDXL with DuraLink™ – provides up to 20 percent more seal life in high impact conditions.

Comparisons to D7E.

BECAUSE UPTIME COUNTS

- Elevated sprocket makes cleanout easier and provides convenient, modular service.

- Standard dozer offers 12-foot (3.7 m) shipping width for easier transport with blade installed.

- Reversible hydraulic demand fan helps remove debris while you work, saving cleanout and maintenance time.

- Easy access under the cab floor if needed. Cab can be removed in about 30 minutes.

- Platform with guard rail makes refueling and DEF fill convenient.

CONNECT TO GREATER EFFICIENCY

- Product Link™ collects machine data that can be viewed online through web and mobile applications.

- Access information anytime, anywhere with VisionLink® – and use it to make informed decisions that boost productivity, lower costs, simplify maintenance, and improve safety and security on your job site.

- The Cat App helps you manage your assets – at any time – right from your smartphone. See fleet location and hours, get critical required maintenance alerts, and even request service from your local Cat dealer.

- Remote Troubleshoot saves time and money by allowing your Cat dealer to perform diagnostic testing remotely.

- Remote Flash updates on-board software without a technician being present, at a time that is convenient for you, potentially reducing update time by as much as 50%.

WASTE HANDLING PERFORMANCE

- Cat Waste Handlers are designed and built from the frame up to take on the challenges of landfill work.

- Specialized guarding, striker bars and seals help protect machine and undercarriage from impact, wrapping and airborne debris.

- Waste cab has impact-resistant polycarbonate doors, eliminating the need for door screens.

- High-debris cooling system with automatic reversing fan and swing-out cleanout access.

- Lights mounted up and away from main debris area for protection, while still giving you plenty of light on the work area.

- Waste undercarriage, center-hole track shoes and landfill blades help optimize performance.

- Laminated thermal shields and insulated Clean Emissions Module.

SUSTAINABILITY

- Optimize machine performance for greatest productivity, while helping improve fuel efficiency and reduce greenhouse gas emissions with a fully automatic 4-speed transmission with lock-up clutch.

- The Cat® C9.3B engine meets U.S. EPA Tier 4 Final, EU Stage V, Japan 2014, Korea Tier 5 and China Nonraod Stage IV emissions standards.

- Cat diesel engines are required to use ULSD (ultra-low sulfur diesel fuel with 15 ppm of sulfur or less) or ULSD blended with the following lower-carbon intensity fuels up to: 20% biodiesel FAME (fatty acid methyl ester) ** or 100% renewable diesel, HVO (hydrogenated vegetable oil) and GTL (gas-to-liquid) fuels. Refer to guidelines for successful application. Please consult your Cat dealer or “Caterpillar Machine Fluids Recommendations” (SEBU6250) for details.

- Cat® Grade with Slope Assist™ helps you avoid costly rework and wasteful fuel burn and greenhouse gas emissions by automating your blade position without a GPS signal.

- Cat® Grade with 3D automates blade movements using a GPS signal helping you follow a grade design, reducing fuel burn and greenhouse gas emissions by improving efficiency and accuracy.

- AutoCarry™ automates blade lift to reduce track slip for maximum efficiency on each pass to help lower fuel burn and greenhouse gas emissions.

- VisionLink® displays the CO2 emissions for monitored assets, calculated by fuel type for the Runtime Fuel Burned each day in a selected date range.

- Remote Flash minimizes downtime and maintenance time while keeping your asset running with maximum efficiency. Alerts for machine updates are sent virtually from your Cat dealer and updates can be deployed without a dealer technician needing to be onsite.

- Remote Troubleshoot decreases maintenance time and keeps your machine running with maximum efficiency by allowing your Cat dealer to virtually test the machine while working. Once a problem is identified, a technician can fix it the first time, saving time and money.

All comparisons to D7E. Productivity, fuel and CO2 emissions vary by application. CO2 emissions calculations based on a reference work cycle using 2.2 U.S. gallons per hour of #2 U.S. diesel fuel. Applies IPCC2006 methodology using U.S. EPA Emissions Hub emission factors. Includes DEF (diesel exhaust fluid) related CO2. Fuel measurements are at 15°C. Estimated average fuel consumption improvements are based on tests or Product Link™ data where available. Productivity improvements are based on test data.

**Engines with no aftertreatment devices can use higher blends, up to 100% biodiesel.