Equipment is as important to construction projects as material is. Moving materials is so much easier with construction equipment — especially the right type and size of equipment. Just as it’s vitally important to have the proper materials for the job, so is selecting the correct machine. Knowing how to choose the right-sized equipment comes with knowledge of what equipment is available and how it matches to your job requirements.

Sizing construction equipment varies depending on your specific application or job that needs to get done. The volume of material that needs moving is a big factor. So are the location and confines of the workplace, as well as environmental considerations like site conditions and, of course, weather. Selecting equipment that’s too small can leave you short on production. Equipment that’s too large can be inefficient on costs, time and transportation requirements.

Most contractors would love to have the biggest and most powerful equipment, just in case they find work that requires larger capacities. But that’s often not practical when it comes to owning and operating costs. Bigger is not necessarily better in the world of construction equipment. Machinery sizes vary across all applications, including industrial, commercial and residential worksites.

Small vs. Large Construction Equipment

Today, you’ll often see a wide assortment of machines working on a single job. They range from large earth movers to mini-excavators, and from small skid steers to big loaders. Each machine has its place and purpose. Equipment size classes are across the board, and the best contractors always strive to get more out of their machines to maximize efficiency, which turns into profit.

Knowledgeable construction companies look for versatility in their machines. They strive to achieve a balance between two variables. One is performance, where there’s a large volume of material to handle. The other is where they need to fit into tight and compact areas. These factors make it difficult to choose between large and small construction equipment. Sometimes, medium construction equipment is the right compromise.

Versatile machines strike a happy medium between size and capability. They offer the benefits of power and load-bearing strength, as well as the economics of low cost of ownership, operation and maintenance. Versatile construction equipment is also able to multi-task by using specialized attachments so the machine can operate in different roles without requiring separate machines that add greater costs to the project.

Compact or mini-construction equipment has made huge inroads onto the nation’s worksites. Small equipment has earned a reputation as the epitome of versatility. Thanks to technology, these machines that seem tiny compared to older behemoths are far more productive when it comes to cost per hour and ability to get the work done. Smaller might be better, and that leads to a question asked by every construction equipment owner and operator across the country.

What Size Equipment Is Right for Me?

Determining what size of equipment is best for you depends on many factors. Primarily, it’s the application or exact task you require the machine to do. It also depends on what you expect as a return on investment. Generally, larger and more complex machines have higher purchase and operating costs, and have to be billed out at a higher rate. Smaller machines are more affordable to own and run, but they don’t command the large dollar-per-hour fees their big cousins do.

Equipment sizes vary according to volume demands. Often, the machine’s physical weight and dimensions affect the capacity more than engine horsepower or hydraulic pressure. Transportation is another prime issue when it comes to deciding on the right-sized piece of equipment. Having to purchase or arrange for large-capacity hauling between worksites can be an additional overhead that doesn’t pay back.

You should weigh your decision on the proper size of construction equipment based on the entirety of your needs and operating budget. These are some of the key considerations to take in when choosing what equipment is right for you:

- Job parameters: Your first consideration when searching for the right equipment is the type of job you take on. Job parameters include type, volume and weight of material as well as general tasks performed, such as hauling, leveling and digging. Different machines fit different jobs, and some are more versatile than others. Considering the scope of your jobs will help you determine which sizes will meet your demands.

- Job location: Your job site will include factors like terrain types, slopes, space restrictions and ground conditions. While you might know you have high capacity demands, a large machine might not work with space constraints or muddy ground conditions.

- Technology: Are you looking for automated features like self-leveling? Perhaps you want an improved cab interior compared to your existing older models. Technology considerations can play a role in the size of your equipment. Smaller models may not have the space for all of the most modern features, so if the latest tech is non-negotiable, consider the options across all sizes.

- Attachment compatibility: Work tool attachments can make your machine more versatile. It’s best to think about what requirements you need to meet with each machine, and if you’re capable of meeting multiple demands with the addition of attachments.

- Safety: Many new machines have safety features that protect the equipment and the operators. Machines that are too big for your job site or too small for the demands of the job could compromise safety. Consider these features and how different sizes may impact safety needs.

- Upfront costs: Your budget will always influence the type of machine you choose. Generally, larger machines come with a large price tag. You may have to compromise on a smaller model to avoid larger upfront costs. If you know you need a larger machine, talk to your dealer about financing options to find a payment solution that works with your budget.

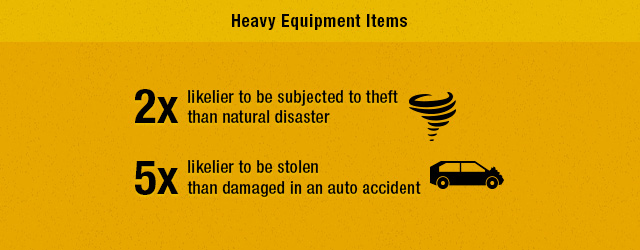

- Return on investment: What are the expected maintenance requirements for a given machine? What will insurance cost? What additional expenses will you pay with financing? Consider these expenses to ensure your purchase will have a strong return on investment.

Different Sizes of Construction Equipment

Just as there’s no one machine that can handle every task, there’s no one-size-fits-all with construction equipment. It starts with what machine you need, then determining what capacity you require. And that depends a great deal on where and when you’ll be using the machine.

Earth moving is the largest area of use for construction equipment. That might be a mini-job like backyard landscaping, a small task like trenching, a medium undertaking such as excavating and backfilling a foundation or a large project such as land clearing, road making or dam building. Other construction equipment areas are building material handling and aerial lifting of workers.

Warren CAT is one of the largest and fastest growing Caterpillar® dealerships in North America. We supply all sizes of top-quality Cat® brand equipment designed and built to handle every mini, small, medium and large project that you can find. Besides excavating and earth moving, Warren CAT supplies many specialized tools for handling all construction materials and making workers’ jobs easier, faster and safer.

We’ll take a look at how Warren CAT can help you choose the right-sized equipment for your construction work, whether that’s moving earth or any other type of material handling. Earth works are Warren CAT’s largest market segment and our specialty. Cat brand earth-movers are divided into five main categories.

- Excavators

- Backhoes

- Wheel loaders

- Bulldozers

- Skid steers & compact track loaders

Each of these construction equipment machines comes in a variety of sizes. Most are designed for specific capacities and applications. However, these machines are highly versatile, especially when equipped with Cat attachments that convert the machine and let it handle many different types and sizes of jobs. Let’s look at each of the five categories in detail, and what your right size might be.

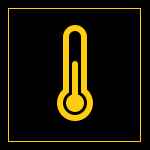

Choosing the Right-Sized Excavator

Excavators are expected to do earth-moving work across the construction scale. They’re found in huge construction projects, where they work in conjunction with a team of other machines to get big work done efficiently and within a large scale of economics. Most excavators are set on tracks for crawling around rough ground, but some Cat excavators are equipped with wheels for faster movement on more sensitive surfaces like asphalt roads or concrete pads.

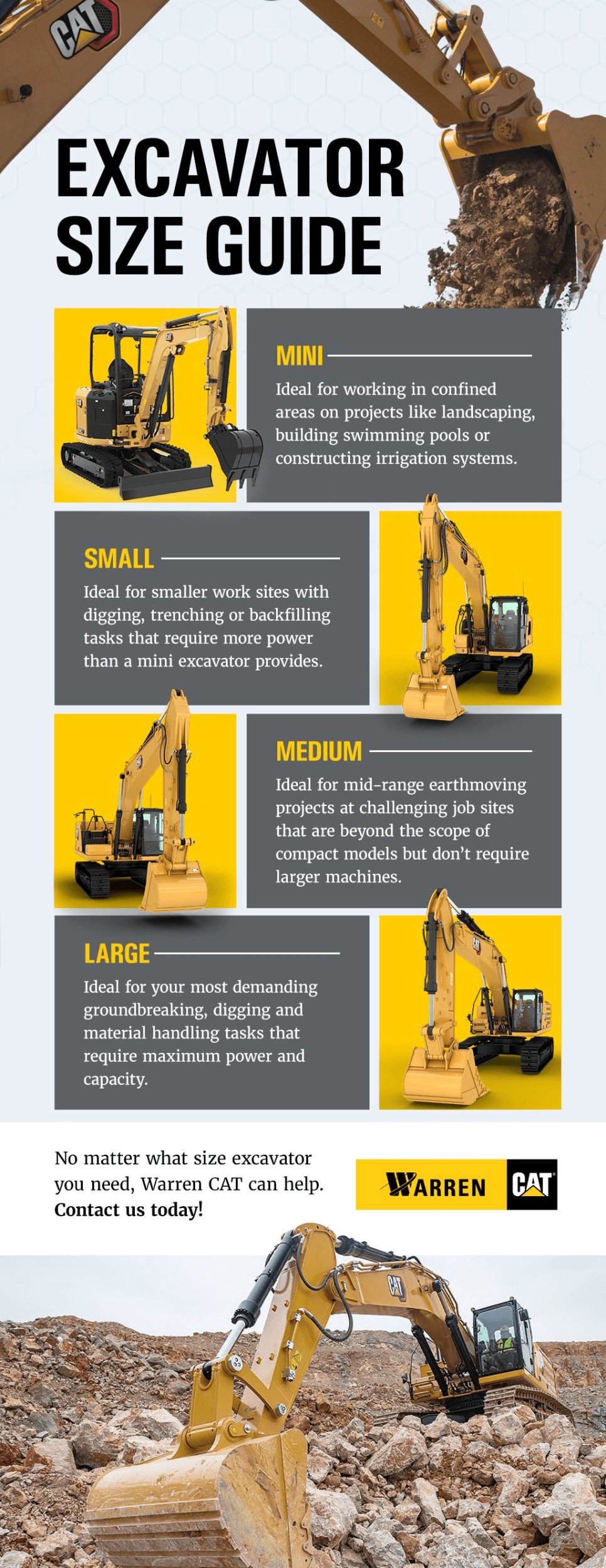

Traditional excavators have an extended boom and a 360-degree rotation swing. They’re used for trenching and carving out foundation holes, demolition, rough and smooth grading, as well as specialty tasks like brush removal. Although excavators range from small to large, they’re normally divided into three distinct size groups.

- Mini or compact excavators are typically the most mobile and easiest to maneuver into tight places. They weigh between two and seven tons. Mini-excavators are the tool of choice for landscapers and construction sites where space is limited and mobility is tricky. Compact excavators are ideal for avoiding damage to the finished ground, or where sensitive pipes, cables and gas lines may be buried. Transportation is easy with mini or small excavators. They’re meant to be pulled by a standard pickup and trailer.

- Standard excavators range between seven and 45 tons, and are the most versatile excavators. They’re large enough to handle most construction jobs in the most common working environments. Standard excavators have plenty of power, but require operating space. At the highest tonnage, these machines can present storage and transportation challenges. Standard excavators are also heavy and will damage finished ground.

- Large excavators are the big industrial workhorses. They can weigh up to 80 tons and require heavy trailers with special transportation permits. Large excavators have immense power and are the answer for big commercial projects. They also have large purchase and operating costs. You rarely find large excavators in an urban environment.

1. Tail Swing Is Important in Choosing the Right-Sized Excavator

Another factor to consider when you’re choosing the right-sized excavator is tail swing. This refers to the rearward extension where the excavator’s engine and counterweight are located. Traditional excavators have rear sides that extend beyond the undercarriage or tracks. As the excavator is rotating, the swing from the tail can be hazardous to nearby objects, including structures and workers. As a rule of thumb, the larger the excavator, the longer its tail swing will be.

Zero tail swing or zero house swing features are designed to keep the excavator’s cab, engine and counterweight within the entire confines of the undercarriage. This lets the operator safely work near obstacles like walls and trees. There’s one disadvantage to zero-swing excavators. To compensate for swing, the excavator’s tracks tend to be set wider apart which makes it harder to drive in tight work spaces.

Boom reach is important regardless of the size of excavator you’re considering. A long excavator boom or arm lets you reach further from the machine’s parked position, but it slows the cycle time. This can be important depending on your location or how fast a truck-filling turnaround time you expect. Shorter arms increase speed, but lessen how far you can handle material.

2. Consider Bucket Design and Capacity

Bucket capacity and design is another consideration when picking the right size of excavator. Buckets have two main configurations. One is a narrow profile with small capacity and is equipped with teeth on the leading edge. This is a trenching or ripping bucket, and it’s used to break up hard ground. The other is a bailing or cleanup bucket that’s wide and has a voluminous capacity. It lacks teeth and is used to load large amounts of material out from the ground or on surface piles.

Bucket capacity is rated in volume measured by cubic yards or cubic meters. Mini-excavators can have small buckets with a fraction of a cubic yard capacity, while standard and large excavators have can handle multi-yard material volumes. Determining what bucket capacity you need is a highly important consideration to take in when sizing your construction equipment.

Engine power is dictated by the excavator’s size, weight and lifting capacity. Larger excavators naturally require larger horsepower engines to drive the hydraulic system which delivers power to the boom and tracks. It’s best to determine the operating parameters like size and capacity for your construction equipment first. Your machine’s engine power will then match its service requirements.

Operator Comfort and Safety Are Important in Choosing Construction Equipment

Excavators are machines where operators spend a great deal of confined time. More so than backhoes, wheel loaders, skid steers and dozers, many excavator operators spend their entire day for weeks on end inside the machine’s cab. They’re subjected to temperature extremes, visibility challenges, ergonomic effects from jarring shock and repetitive motions from control handling.

Some smaller, mini-excavators have an open, ride-on operator station, but all standard and large-sized machines have enclosed cabs. They have heating and air conditioning systems, as well as glare-resistant glass and even exterior protection from hazardous materials that can be loosened or felled by excavation activities.

Many new excavators have ergonomically designed controls like joysticks and left/right-hand conversions. Seats and restraints are designed with operator comfort and safety in mind. Some machines even come with audio and communication systems, as well as hearing protection and dust filtration apparatus. All these features should be accounted for when selecting the right-sized equipment. Sometimes, for operator comfort and safety, it’s best to step up one size in machinery.

Backhoes Are Available in Different Sizes

Backhoes perform many of the same tasks as excavators, such as trenching and loading. Like excavators, backhoes are available in different sizes, depending on the intended use. The main size factors in backhoes are their designed depth of digging or reach, as well as their loading capacity.

Where all an excavator’s functions are handled by one boom and bucket, a backhoe is a two-ended machine. The boom with the trenching bucket is on the rear end, while the large loading bucket or scoop is on the front. This makes a backhoe very time-efficient in handling multiple roles without having to stop and change buckets.

Another big time advantage is a backhoe’s mobility. Thanks to their rubber tires, backhoes can travel at much faster speeds than an excavator. They can also be safely operated on finished surfaces like pavement and concrete. Backhoes are indispensable in municipal operations where excavators are limited by tracks and sheer size.

When choosing a backhoe size, consider the role you expect it to fill. That includes location and types of material to be handled. You also need to determine load capacity, which will dictate machine size and engine power. Operator convenience, comfort and safety are also important.

Choose a Wheel Loader According to Capacity Requirements

Wheel loaders are commonly called front-end loaders. They’re not like backhoes that have a trenching and digging boom. Wheel loaders have one main purpose, and that’s to quickly and efficiently scoop up loose material and place it into containers like dump trucks and box trailers.

You’ll commonly see wheel loaders scurrying around gravel pits or aggregate supply depots. They depend on a combination of speed and load capacity to be efficient. Wheel loaders are continually switching between forward and reverse, and are required to make tight turns in small spaces.

The most important consideration in picking the right wheel loader is its bucket capacity. This determines the machine’s size. You need to consider your working environment and time frame allowed for loading. You can nicely get by with a small loader if you’re only dealing with light-duty trucks that take landscape supplies, but if you’re in the gravel or large aggregate industry, a big loader is the only way to go.

Another factor to consider is portability. If the loader remains stationary in a yard or pit, a larger machine may be suitable. However, if you regularly mobilize a wheel loader, you need to consider trailer and truck size. Here, a smaller machine might have a better return. Even if it takes a few more scoops per truckload, it might be more cost effective to slip down a size or two.

Bulldozers Have One Primary Purpose

Dozers are designed to push and spread volumes of earth across a relatively flat area. The volume or amount of material you need to move is the primary factor in sizing a bulldozer. The nature of the material also comes into play, as wet, heavy soil requires a larger machine than dry, granular material.

For light-duty applications, a small dozer may be fine. For large operations, however, there’s nothing like the brute strength and sheer pushing power a huge machine can deliver. Besides the blade size, the other main consideration in picking a dozer as construction equipment is its physical size or footprint. Larger machines take larger space. They also take larger mobilization equipment, and it all adds to greater cost.

When picking the right-sized bulldozer, make a careful assessment of the conditions you’ll be operating in. Like other machines, it’s wise to err on the side of caution. Too large a dozer may be hard to move and handle. Too small may be unable to do the job.

Skid Steers and Compact Track Loaders Are Highly Versatile

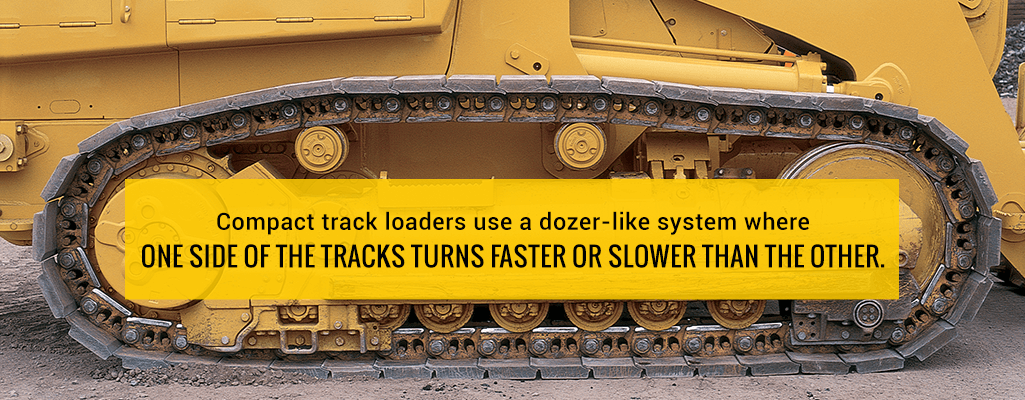

The main difference between a skid steer and a compact track loader is the mobility system. Skid steers are usually rubber tires and rely on locking either the left or right wheels to turn. Compact track loaders use a dozer-like system where one side of the tracks turns faster or slower than the other. Each machine has the ability to turn in its own radius.

These versatile machines are extremely popular on construction sites. They vary in size, but all are designed to be mobilized on a trailer or back of a dump truck. Often, skid steers are used in teamwork with other construction equipment because they’re fast, compact and economical. They’re also easy to operate and require minimal skill and training.

Choosing a skid steer or compact loader size really depends on where and what it’s intended to be used for. Like other machines, the larger units have bigger capacity and perform heavier duties. But there’s a cost involved, and that needs to be weighed. It’s a matter of return on investment compared with the ability to complete a given job.

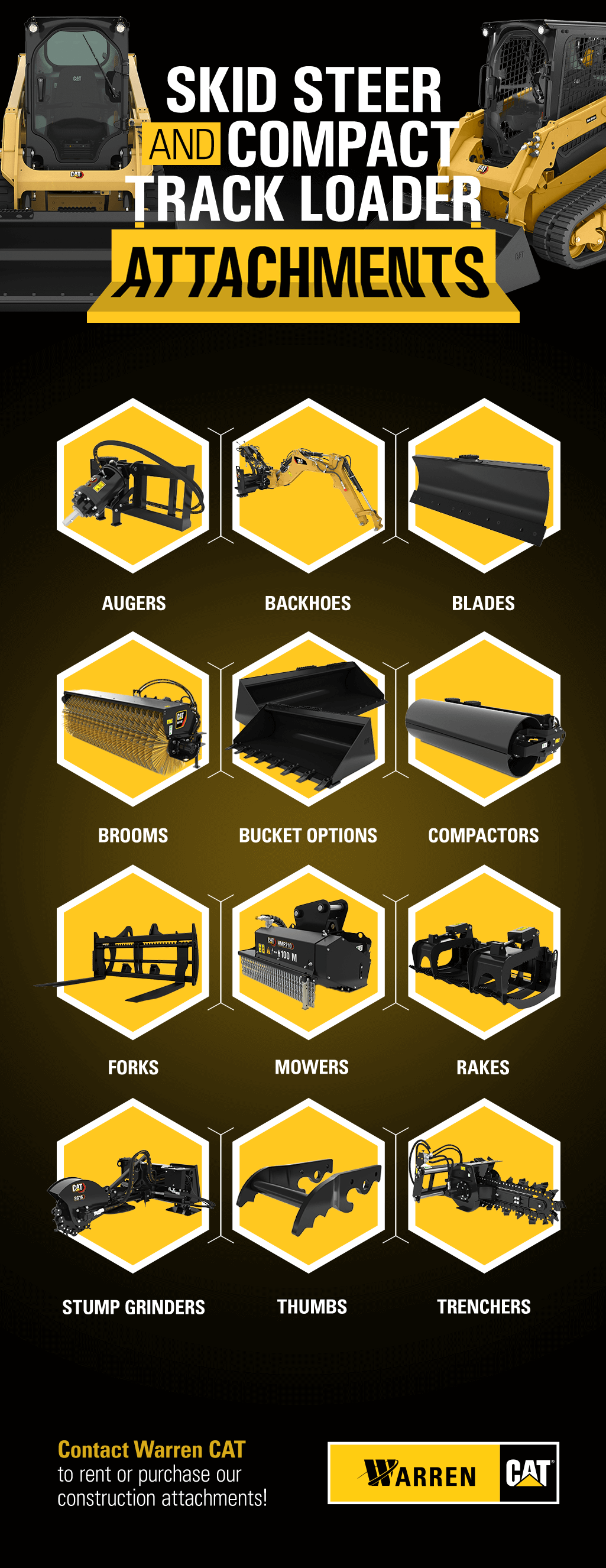

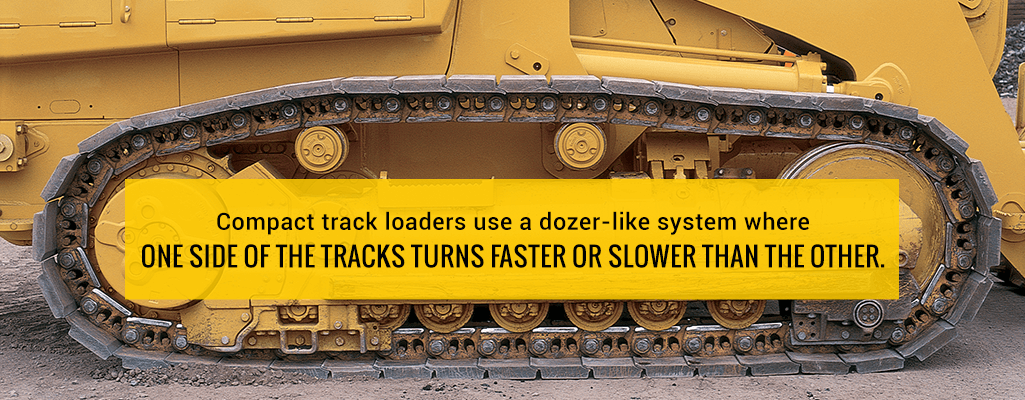

Attachments Make All Sizes of Construction Equipment Versatile

One thing that makes skid steers and compact track loaders so versatile is the remarkable array of attachments available. Attachments turn the machine into something altogether different at a fraction of the cost of buying another dedicated machine. Warren CAT has a wide assortment of Cat brand attachments for all sizes of skid steers and compact track loaders. Here are a few of the most popular Cat attachments.

Adding attachments to your fleet can be an excellent way to elevate your newest fleet additions. For example, if a backhoe is not in your current budget, using a backhoe attachment on your skid steer can help your operation until you’re ready for a larger investment.

These attachments can also add extra support to a given task. For instance, you may have wanted a bigger dozer, but your job site did not have the space. Use a range of blade and bucket options to keep up with earthmoving demands utilizing a smaller machine.

Warren CAT Is a Top Supplier of Cat Construction Equipment

No matter what size of construction equipment is right for your job, Warren CAT is here to help you select it. Warren CAT serves customers in many locations in West Texas and Oklahoma. Whether you need a small skid steer with multiple attachments, or a large excavator with a long reach and big capacity, Warren CAT has the inventory and experienced staff to help you make the right choice.

Our capability to serve customers and our reputation as a world-class dealership make Warren CAT the perfect Cat brand construction equipment outlet to partner with. Contact us online today for more information.