Unlocking efficiency is a common goal across construction teams. Thankfully, there are plenty of strategies you can leverage to accomplish this goal. From simple improvements to long-term changes, you can tweak your existing processes or implement new methods to reach long-lasting success.

1. Improve Your Planning

Proper planning is key to construction site efficiency. The construction industry constantly faces new challenges, roadblocks and innovations. Project planning, crafting budgets and anticipating potential pain points can prepare you to overcome obstacles and empower you to control operations smoothly.

Consider budget allocation, timelines, resource availability, project scope, communication lines and potential risks. Outline your goals, proper actions for achieving them and ideas for overcoming pitfalls you may anticipate. These plans will guide your future decision-making and empower your team to bounce back quickly.

2. Offer Operator Training

Training opportunities give workers the knowledge and skills to operate machinery safely and efficiently. With proper education, they’ll understand the best practices for operating equipment.

Trained operators can better identify equipment issues, empowering you to administer fixes as soon as possible to minimize downtime and extend equipment life spans. Additionally, a properly trained team may feel more comfortable and confident operating machines, leading to fewer accidents and minimizing costly errors on the project site.

3. Enhance Project Scheduling

Meeting project timelines is crucial to remaining competitive and ensuring customer satisfaction. Although improving planning will likely impact project scheduling, there are some specific actions you can take to enhance this process.

For example, implementing software solutions can allow you to assign specific tasks to team members or groups. You can also use risk assessments to determine where to improve project activities while reducing errors and accidents. Proper resource allocation and automated material purchasing can help you prevent downtime and keep your team moving.

4. Implement Preventative Maintenance

Equipment maintenance is important for several reasons. Preventative maintenance ensures equipment integrity, allowing you to maximize your investment through prolonged life spans and fewer component issues. Proper maintenance also enhances worker safety.

Further, following specific maintenance tips can help you save money by allowing you to identify minor issues before they grow into significant and costly problems. To keep your equipment in optimal condition, you should establish a maintenance plan and work with a reputable equipment maintenance service provider in your area.

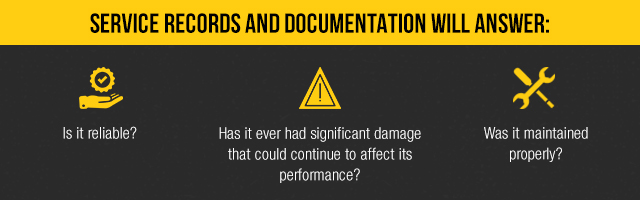

5. Document Your Progress

Insights hold power; documenting your progress can inform future decisions and help you find the best ways to reach operational efficiency. Your team should use data to determine every aspect of your projects, from resource allocation to material spending to machine rentals.

You can find comprehensive software solutions to gather data and use artificial intelligence and machine learning to identify trends for further time savings and enhanced productivity. This information can help you find operational inefficiencies you need to address and provide you insights to highlight when you’re moving in the right direction.

6. Boost Team Communication

Efficient communication can boost team operations by ensuring everyone is on the same page, aligning actions with business goals and reducing errors associated with miscommunication. Construction teams often work with many individuals, including architects, engineers, contractors, customers and project managers. It’s crucial to enhance communication with all relevant individuals to enhance efficiency and project accuracy.

7. Set Realistic Goals

Many construction teams have ambitious goals. While aiming high can motivate, failing to reach unrealistic goals can be discouraging. When setting business goals, consider your realistic scope and how you can actively work to achieve your objectives.

You can also use insights about your business and the industry to determine baselines for your objectives. Establish performance measurements to monitor team progress and highlight the impact of team efforts. After reaching a goal, recognize your team for their hard work to boost employee engagement.

8. Leverage New Technologies

Modern technologies offer many new features and controls for enhancing productivity, operator comfort, safety and efficiency. Choosing a reliable equipment provider gives you access to the latest innovations and cutting-edge technology for construction equipment. These technologies can highlight machine needs, offer enhanced customization and improve precision and accuracy.

9. Organize Your Inventory

Proper organization can improve efficiency by reducing the time it takes to find or access materials and equipment. Keep the job site and inventory organized by removing debris, keeping items off the floor or ground and utilizing a system for removing or replacing items. Organization can also reduce accidents like trips or falls and prevent machine damage.

10. Utilize Cat® Equipment

Optimizing construction efficiency also involves leveraging reliable, powerful and durable equipment. Leading manufacturers use proven technologies and strategies to deliver robust construction solutions.

Cat equipment offers the versatility and reliability construction teams need to enhance efficiency and save time and cost. Additionally, choosing a local Cat dealer ensures you have access to equipment services and comprehensive customer support if you encounter a problem.

11. Gather Team Feedback

Your workers have firsthand knowledge about your equipment, jobs and processes. Interacting with your operators and builders can help you identify problems you were unaware of and gain insight into worthwhile changes that can boost productivity.

Ask for feedback regarding equipment usage, training, safety measures and maintenance needs. After making any alterations, check in with your team to discover what works and what needs improvement.

12. Prioritize Worker Safety

Worker safety is crucial on construction sites. Along with protecting your team from accidents and injuries, prioritizing safety can enhance efficiency.

When teams have to navigate project site hazards, they may experience setbacks. For instance, slower task completion can lead to missed deadlines. Accidents or injuries can cause downtime if you lack the workforce necessary to complete certain tasks. Furthermore, when your operators work in safe conditions, they can dedicate more headspace to project tasks and feel confident in their capabilities and your level of care.

Boost Construction Efficiency With Warren CAT

At Warren CAT, we provide complete solutions to meet every customer’s needs. As your certified Cat dealer in Oklahoma and West Texas, we can help you find the right equipment for enhanced efficiency on the job site.

We offer a wide range of new machinery and used equipment for purchase, or you can choose reliable equipment rentals to satisfy unique project requirements. Browse our offerings today to discover what we have in stock. Have questions about our selection or how to improve construction productivity with Cat equipment? Call 866-292-7736 for expert assistance.