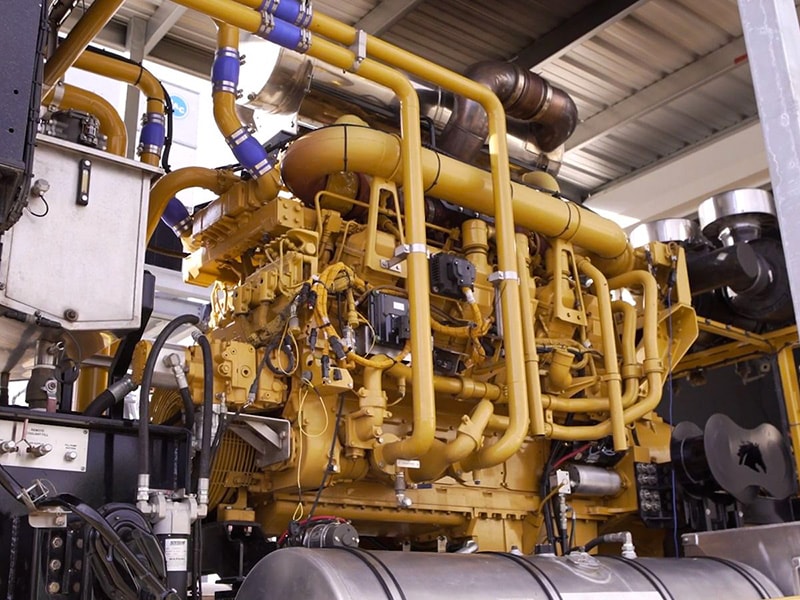

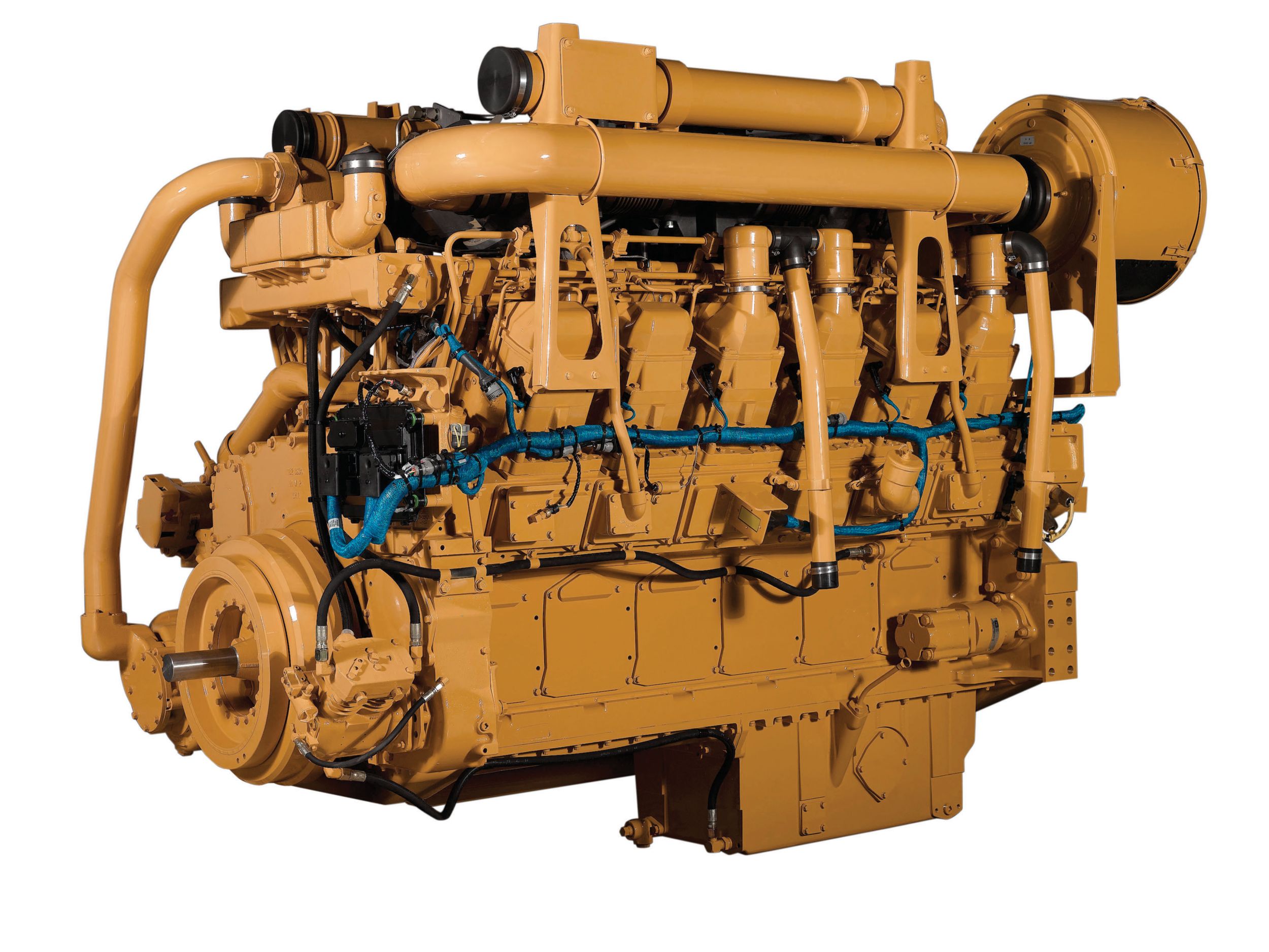

Cat® Dynamic Gas Blending™ is a dual-fuel technology that allows existing Cat diesel engines to burn natural gas, diesel fuel or a combination of the two. This revolutionary technology includes highly intuitive software which automatically adjusts the engine control to provide an optimal blend of natural gas and diesel fuel. A DGB engine begins as a pure diesel engine and injects natural gas as the inlet air temperature increases. As the natural gas is injected, the amount of diesel fuel being consumed decreases accordingly.

Considering the switch to Cat DGB engines on your frac trailers? That’s smart thinking. DGB allows your engines to burn natural gas — including field gas — as well as diesel. It’s a proven way to lower fuel costs and reduce emissions without sacrificing the diesel engine performance you’ve come to rely on.

Cat DGB engines for well service let you operate on the industry’s wide range of fuels, including CNG, LNG, pipeline gas and even field gas as an alternative to flaring. With Cat DGB engines, you could cut your diesel consumption by as much as 85%, while maintaining all the power, reliability and ease of maintenance of our diesel models. And unlike other options on the market, DGB gives you the flexibility to run your engines on 100% diesel when gas isn’t available.

Whether you’re looking to start fresh with Tier 4 Final DGB engines or upgrade your existing Tier 2 engines to DGB, we have you covered. In fact, Caterpillar® is the only engine manufacturer with dual fuel solutions that meet both sets of emission standards. There are some key differences between the two offerings, though, so take a look at the details below to determine which option is best for your fracking operation.

| Cat 3512E DGB Engine – U.S. EPA Tier 4 Final Certified* | Cat 3512C DGB Engine – Meets Tier 2 Levels | |

|---|---|---|

| Installation | Turnkey, factory-installed solution that includes integrated aftertreatment support – no downtime | Upgrade kits — allow time for installation |

| Base Engine | High Pressure Common Rail platform with Exhaust Gas Recirculation – same as Tier 4 Final diesel engine | MEUI-A (Mechanically Actuated Electronically Controlled) platform |

| Maximum Diesel Displacement | 85% | 65% |

| Fuel Range | 850-1250 LHV | 850-1250 LHV |

| Combustion Control | Achieved via multiple technologies that combine to maintain emission levels and keep displacement high: · In-Cylinder Pressure Sensing (ICPS), which monitors combustion of each cylinder for more precise control · Compressor bypass control · SOGAVs (gas metering devices) · Control software · Oxidation catalyst and compression ratio |

Achieved via exhaust temperature and knock sensors |

| Gas System | Individual cylinder gas metering system | Fumigated gas system |

| Filtration | Integrated gaseous fuel filtration with pressure monitoring for maintenance notification | Customer-supplied |

* U.S. EPA Tier 4 Final Nonroad, 49-State

A DGB engine can offer a wide variety of benefits for your company. It can:

It depends on your priorities. If you’re building a new fleet, or have the resources for a complete repower, 3512E DGB engines deliver the best overall performance, savings and environmental footprint. If you’re looking for a cost-effective way to upgrade your existing fleet, 3512C DGB kits may be the answer.

Either way, the ability to burn field gas as well as diesel means you’ll likely see big savings on your fuel bill. Warren CAT Power Systems experts can help you weigh your choices and put the right DGB solution to work on your frack trailers.

DGB technology is ideally suited for the oil and gas, electric power, mining, marine and railroad industries. Whether you need new engines already configured with DGB capabilities or want to retrofit your existing engines and generator sets, Warren CAT Power Systems is your expert source for dynamic gas blending applications. We can upgrade your current engine hardware with complete, fully-compatible DGB retrofit kits without requiring changes to core engine components.

Contact us to learn more about how DGB technology can lower your fuel costs and help you meet emissions requirements — without having to sacrifice performance and productivity.