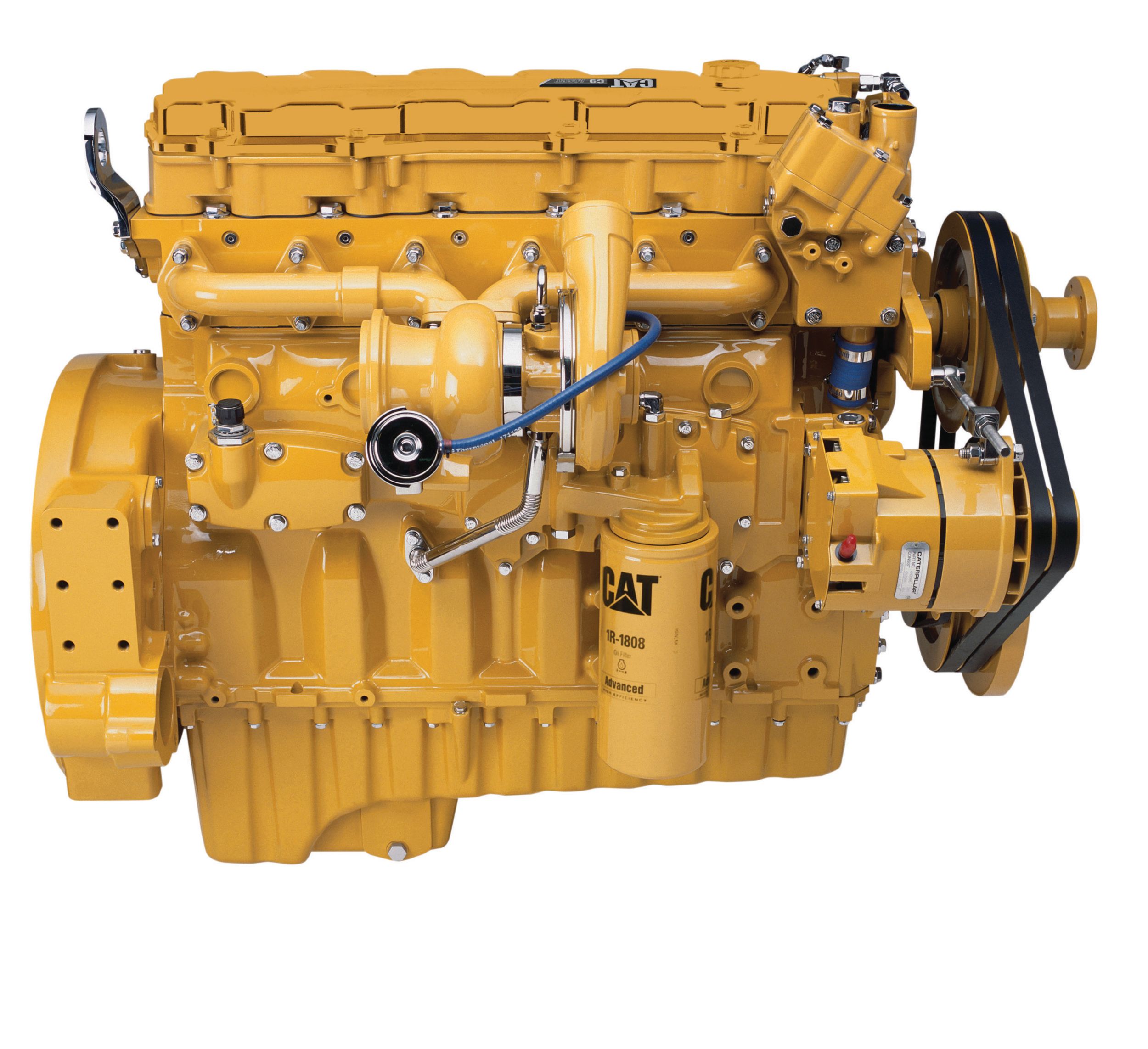

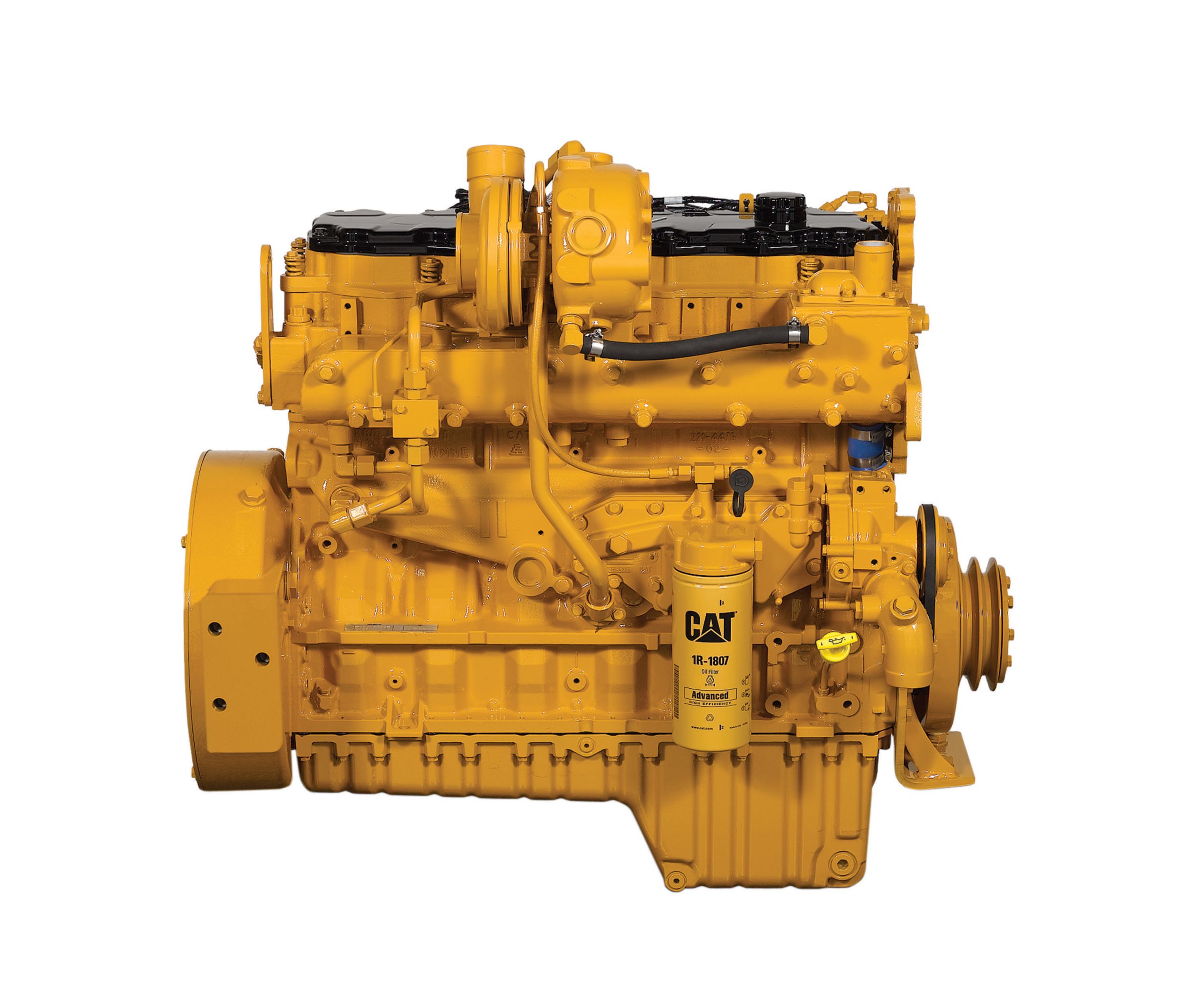

C9 ACERT™ Water Cooled Manifold Engine

THE RUNDOWN

Engine Design

- Proven reliability and durability- Robust diesel strength design prolongs life and lowersowning and operating costs- Broad operating speed range- PTO drive options provide flexible access to auxiliarypower for pumps and other needs

Advanced Digital Engine Management

ADEM A4 engine management system integrates speed control, air/fuel ratio control, and ignition/detonationcontrols into a complete engine management controlsystem with integrated digital ignition, engine protectionand monitoring

Air System

- Water-cooled exhaust manifold and turbo maintainATEX-compliant skin temperature during operation- Air Inlet shut-off enables emergency shut-off foroperator

Improved Serviceability

- Front, right, and rear dipstick- Remote oil and fuel filters- 12V and 24V electronic systems to improve applicationflexibility

Optional Equipment

- Air inlet for cold starting capability- Messenger display for operator friendly diagnostics- Spark arresting muffler

Custom Packaging

For any petroleum application, trust Caterpillar to meetyour exact needs with a factory custom package. Cat®engines, generators, enclosures, controls, radiators,transmissions — anything your project requires — can becustom designed and matched to create a one-of-a kindsolution. Custom packages are globally supported andare covered by a one-year warranty after startup

Transmissions

Caterpillar has a full line of engine/transmission packagesthat can be fully integrated with your axle, hydraulics, andoperator interface. Cat transmissions deliver continuousoperation under full load, smooth shifting at any speed,and maximum up time, with unmatched durability andeasy maintenance.

Full Range of Attachments

Large variety of factory installed engine attachmentsreduces packaging time

Testing

Every engine is full-load tested to ensure proper engineperformance.

Product Support Offered Through Global Cat Dealer

- More than 2,200 dealer outlets- Cat factory-trained dealer technicians service everyaspect of your petroleum engine- Cat parts and labor warranty- Preventive maintenance agreements available for repairbefore-failure options- S•O•SSM program matches your oil and coolant samplesagainst Caterpillar set standards to determine:- Internal engine component condition- Presence of unwanted fluids- Presence of combustion by-products- Site-specific oil change interval

Over 80 Years of Engine Manufacturing Experience

Ownership of these manufacturing processes enablesCaterpillar to produce high quality, dependable products.- Cast engine blocks, heads, cylinder liners, and flywheelhousings- Machine critical components- Assemble complete engine

Web Site

For all your petroleum power requirements, visit www.cat.com/oilandgas.

General Specifications

| Maximum Rating | 340.0BHP |

| Displacement | 538.0in³ |

| Minimum Rating | 325.0BHP |

| Governor and Protection | Electronic (ADEM™ A4) |

| Aspiration | Turbocharged-Aftercooled |

| Flywheel and Flywheel Housing | SAE 1 or 2 |

| Flywheel Teeth | 113 (SAE 1), 134 (SAE 2) |

| Rotation from Flywheel End | Counterclockwise |

| Stroke | 5.8in |

| Bore | 4.4in |

Emissions

| Emissions | EPA and CARB Non-Road Tier 3,EU Stage IIIA, EPA Marine Tier 2, IMO Tier II |

Dimensions

| Length | 43.0in |

| Width | 32.6in |

| Height | 40.3in |

| Weight | 1576.0lb |

Capacity for Liquids

| Lube Oil System - Refill | 8.0gal (US) |

| Cooling System | 3.7gal (US) |

Standard Equipment

Air Inlet System

- Turbocharger, separate circuit (SCAC) or remote (REMAC)aftercooler

- Single, right-side, center-mounted turbo with water-cooledturbine housing

- Air inlet 101.6 mm (4 in) connection type

Control System

- Electronic governing, PTO speed control

- Programmable ratings

- Cold mode start strategy

- Automatic altitude compensation

- Fuel cooled ECU

- Power compensation for fuel temperature

- Programmable low and high idle

- Electronic diagnostics and fault logging

- Programmable monitoring system (engine speed, temperature,pressure)

- J1939 broadcast (diagnostic and engine status)

- Certified electrical control system (hazardous environment only)

- Derated engine: automatic ambient temperature compensation

Cooling System

- Thermostats and housing, RH forward-facing outlet — 51 mm(2.01 in) connection

- Jacket water pump — belt-driven, centrifugal

- Water pump — inlet RH facing downward 63 mm (2.48 in)

Exhaust System

- Exhaust manifold — water-cooled

- Single, right-side, center-mounted turbo with water-cooledturbine housing

- Rear facing turbo exhaust 81.8 mm (3.22 in) connection, nonV-band clamp

Flywheels and Flywheel Housing

- Mandatory selection of:SAE No. 1 or SAE No. 2 flywheel and housing, SAE standard rotation

Fuel System

- HEUI fuel system

- Fuel filter — secondary, LH (2-micron high performance)

- Fuel transfer pump — left front

- Fuel priming pump — left front

Lube System

- Crankcase breather — LH

- Crankcase fumes disposal — with integrated service indicator, LH

- Oil cooler — RH

- Oil filter — RH

- Oil pan — front sump

- Oil filler — top mounted

- Oil level gauge — LH side

- Oil pump — gear-driven

- Oil valve sampling

- Preservation of turbocharger, flywheel, and crankcase

Power Take-Offs

- Crankshaft drive pulley — 2 grooves, 190 mm (7.5 in) diameter,22.3 mm (7/8 in) wide

General

- Vibration damper

- Lifting eyes

- Automatic variable timing — electronic

- Literature

Mandatory Options

- Flywheel housing and flywheel

- Throttle position sensor and/or throttle control

- (Non-hazardous environment only)

- Primary filter/water separator

- Turbo orientation

Optional Equipment

Air Compressors

- Air compressors

- Air compressor governor

Air Inlet System

- Air cleaner

- Precleaner

- Air inlet elbow

- Air shutoffs

Charging Systems

- Charging alternators

- Alternator mounting

- Alternator belt tensioner

- Alternator pulleys

- Alternator guards

Cooling System

- Radiators

- Fan drive and pulley — f/u/w radiator packages

- Fans f/u/w radiator packages

- Coolant level sensor

- Fan drive mountings

- Fan adapters

- Fan adapter for blower fans

- Fan pulleys

- Fan height instructions

- Vee belts for customer-supplied radiators

- Suction fans and blower fans

- Water inlet elbows

- Dry charge coolant conditioners

Emissions Certifications

- IMO certification

Exhaust System

- Flexible fitting

- Turbocharger exhaust outlet adapters

- Elbows, flange, pipes, clamp

- Rain caps

- Manifolds

- Mufflers

Flywheels and Flywheel Housing

- Crankshaft seal

Fuel System

- Flexible fuel lines

- Water separator and fuel filters

- Fuel cooler

Instrumentation

- Gauges and instrument panels

- Interconnect harness

- Voltmeters

- Gauge mounting

- Ammeter

Lube System

- Oil pans

- Drain and cover

- Oil level gauges

- Remote oil filter

- Oil fillers

- Lubricating oil

- Fumes disposal

Mounting System

- Structural steel base

- Engine support — front and rear

Power Take-Offs

- Enclosed clutch

- Clutch supports

- Flywheel stub shaft

- Hydraulic pump drives

- Hydraulic gear pumps

Starting System

- Starting aids

- Electric starting motors — 12V and 24V

- Battery sets — 12V and 24V (dry)

- Battery cable

General

- Tool set