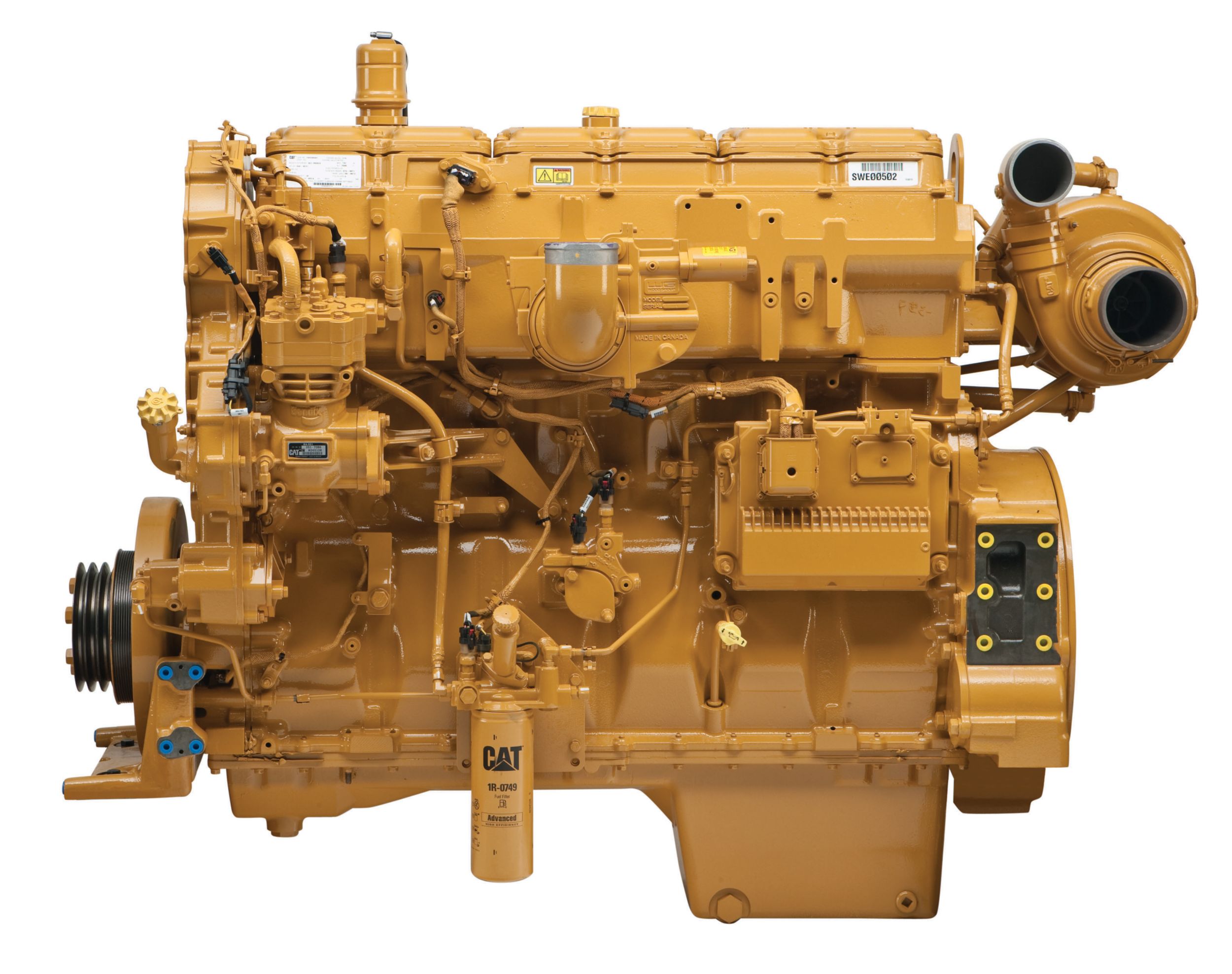

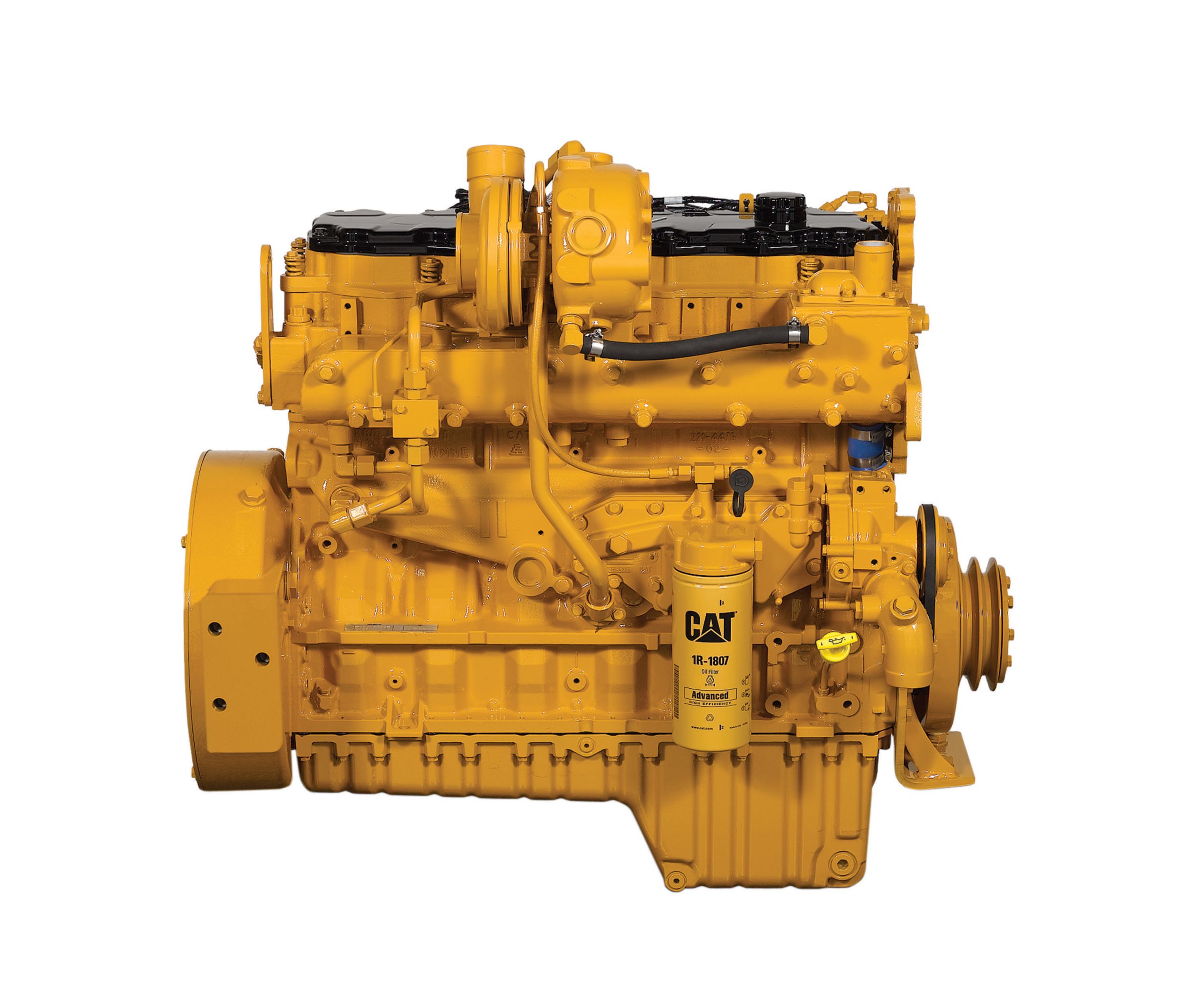

C15 ACERT™ Water-Cooled Mainfold Engine

THE RUNDOWN

Driving Down Total Cost of Ownership

• World-class reliability and durability • Improved serviceability versus the competition • Industry-leading component overhaul life • Rugged Caterpillar testing on all components improves uptime

Advanced Digital Engine Management

ADEM A4 control system providing integrated ignition, speed governing, protection, and controls, including detonationsensitive variable ignition timing. ADEM A4 has improved: user interface, display system, shutdown controls, and system diagnostics.

Custom Packaging

For any petroleum application, trust Caterpillar to meet your project needs with custom factory generator sets and mechanical packages. Cat engines, generators, controls, radiators, and transmissions can be custom designed and matched in collaboration with our local dealers to create unique solutions. Custom packages are globally supported and are covered by a one year warranty after startup.

Custom Packaging

For any petroleum application, trust Caterpillar to meet your project needs with custom factory generator sets and mechanical packages. Cat engines, generators, controls, radiators, and transmissions can be custom designed and matched in collaboration with our local dealers to create unique solutions. Custom packages are globally supported and are covered by a one year warranty after startup.

Transmissions

• Caterpillar has a full line of engine-transmission packages that can be fully integrated with your axle, hydraulics, and operator interface. • - C15 ACERT™ Cat optimized transmission matches: TH35-E81, CX31-P600, CX35-P800 • Hazardous Location Certification of the Cat transmission is currently the responsibility of the OEM/packager

Product Support Offered Through Global Cat Dealer Network

• More than 2,200 dealer outlets • Caterpillar factory-trained dealer technicians service every aspect of your petroleum engine • Caterpillar parts and labor warranty Preventive maintenance agreements available for repairbefore-failure options

Over 80 Years of Engine Manufacturing Experience

Ownership of these manufacturing processes enables Caterpillar to produce high quality, dependable products.

Over 80 Years of Engine Manufacturing Experience

Ownership of these manufacturing processes enables Caterpillar to produce high quality, dependable products.

Web Site

For all your petroleum power requirements, visit www.cat.com/oilandgas.

General Specifications

| Maximum Rating | 540BHP |

| Displacement | 927.6in³ |

| Aspiration | Turbocharged - Aftercooled |

| Flywheel and Flywheel Housing | SAE No. 1 |

| Flywheel Teeth | 113 (SAE 1) |

| Stroke | 6.75in |

| Bore | 5.4in |

Emissions

| Emissions | IMO Tier II Certified, Marine Tier 2 Certified, Marine Tier 3 Capable |

Dimensions

| Length | 54.0in |

| Width | 37in |

| Height | 48.0in |

| Weight | 2743.0lb |

Standard Equipment

Air Inlet System

- Remote-mounted aftercooler with shutoff, 90° turbo inlet connection, 101.6 mm (4") hose connection with shutoff; separate circuit aftercooler with straight turbo inlet connection, 127 mm (5") hose connection

Control System

- Electronic governing, PTO speed control, programmable ratings, cold mode start strategy, automatic altitude compensation, power compensation for fuel temperature, programmable low and high idle and TEL, electronic diagnostics and fault logging, engine monitoring and protection system (speeds, temperature, pressure), J1939 broadcast (diagnostic, engine status and control)

Cooling System

- Thermostat and housing — outlet vertical; jacket water pump — gear-driven, centrifugal; RH front water pump inlet

Exhaust System

- Right rear turbo exhaust, watercooled turbine housing, carbon steel exhaust manifold — wet

Flywheels and Flywheel Housing

- SAE 1 flywheel housing standard, see price list for flywheel options

Fuel System

- Electronic unit injector; fuel priming pump — upward angled; engine-mounted secondary fuel filter, front-mounted fuel transfer pump — LH front; fuel sample valve — mounted on fuel filter base

Lube System

- Oil cooler; RH oil filter; rear sump 38 L oil pan; valve cover oil fill, optional front oil fill; oil gauges standard with LH and RH access; oil valve sampling on oil filter base; remote-mount oil filter kit

Mounting System

- Front support with mounting provision for LH or RH alternators

Power Take-Off

- SAE B options for SCAC and REMAC: single cylinder ATEX air compressor; dual cylinder air compressor, SAE B drive adapter; SAE A drive for REMAC

Front Engine Accessory Drive

- 3 v-groove standard — optional 4 and 5 groove 203.2 mm (8.0") diameter crankshaft, 17.5 mm (11/16") v-belt; optional v-belt or 8-groove accessory drive for 240.39 mm (9.46") diameter pulley; LH and RH mounting poly v-belt; CSA 24V 65 amp alternator — LH and RH mounting poly v-belt; variable fan heights and ratios with 3 and 4 groove fan drives (see Price List)

General

- Vibration damper, lifting eyes, automatic variable timing — electronic, electronic installation kit 70-pin connector (connectors, pins, sockets), literature GP Owner & Operator, paint