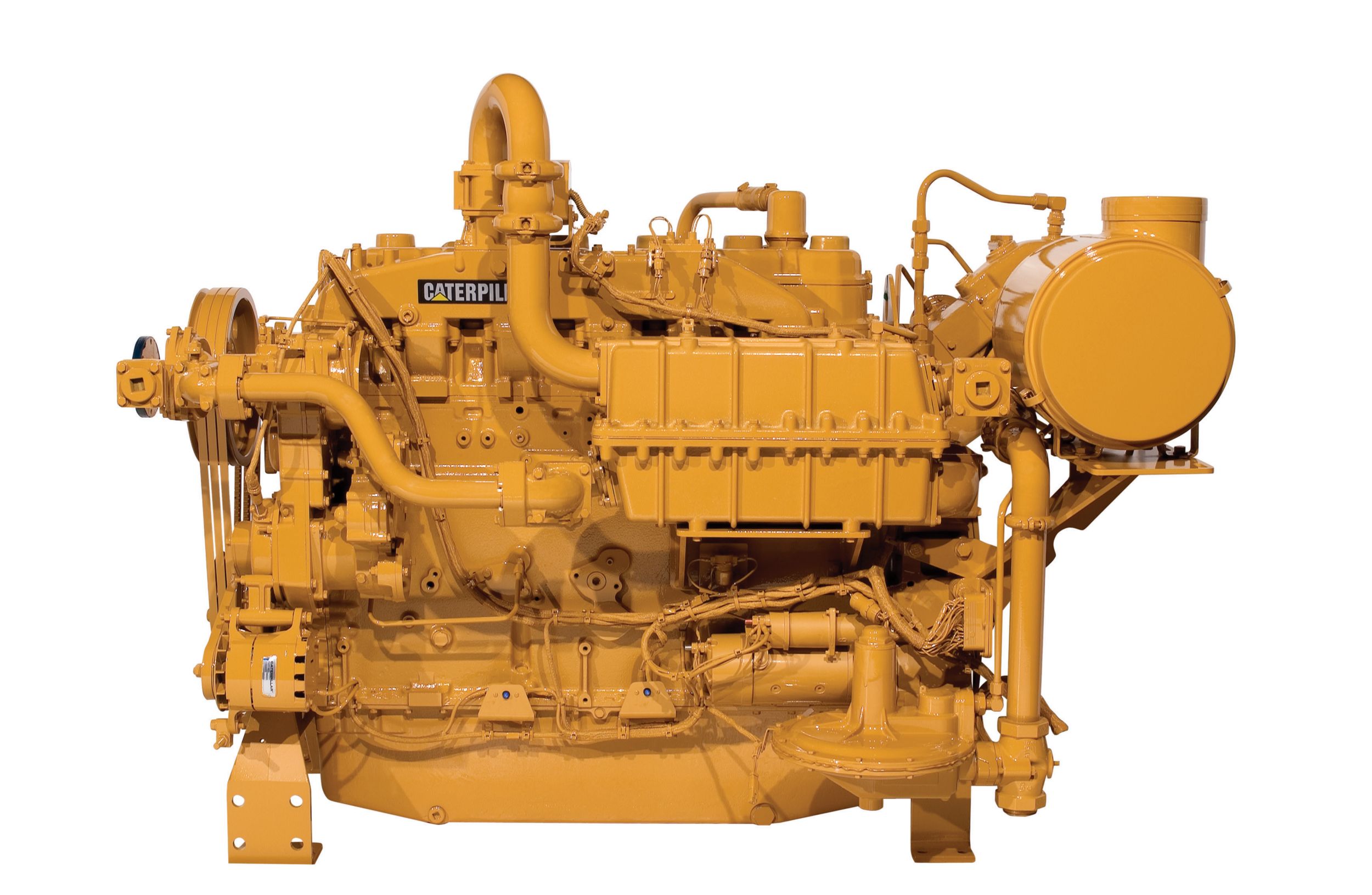

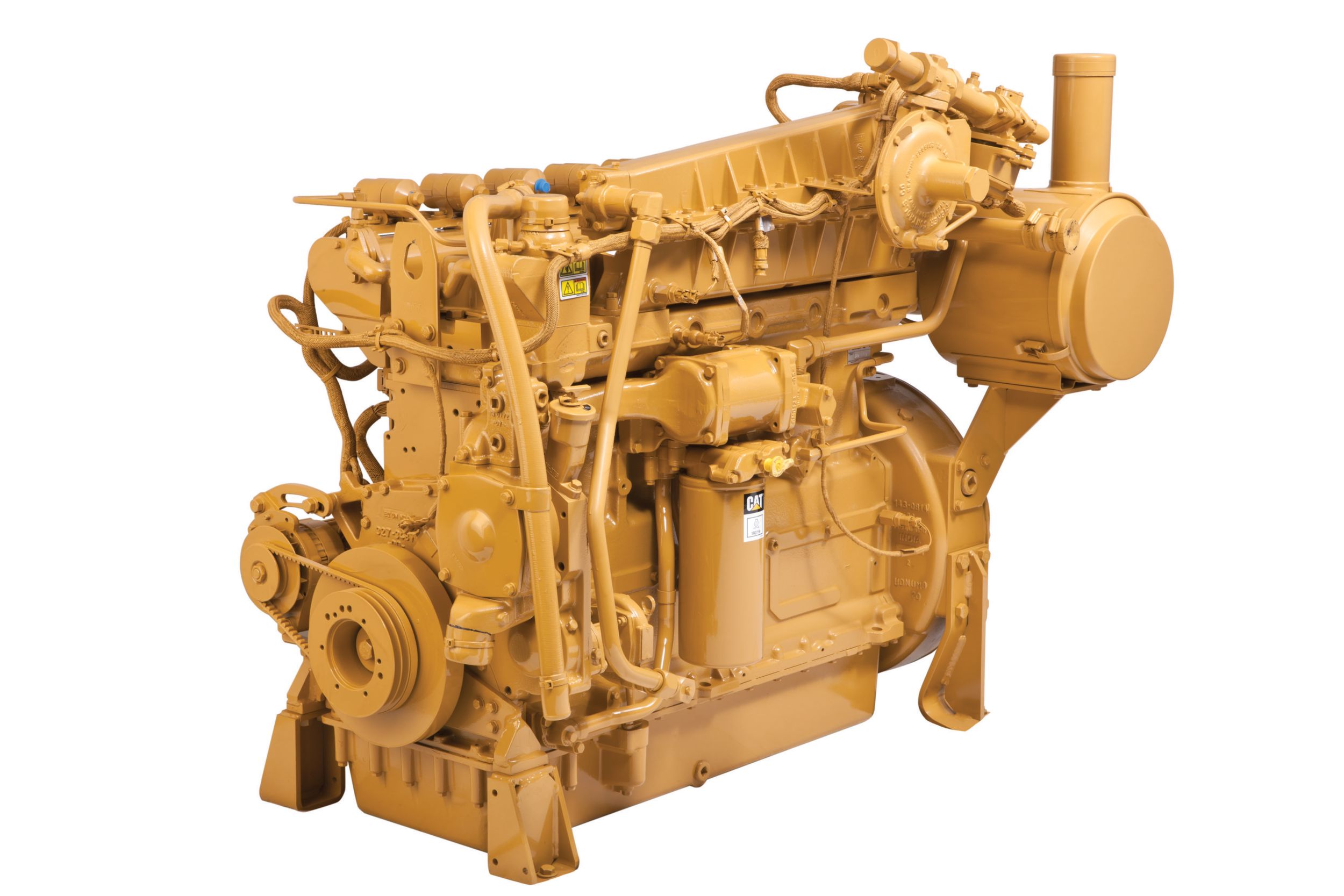

G3304B Gas Compression Engine

THE RUNDOWN

Advanced Digital Engine Management

The ADEM A4 system represents the next generation of engine management systems while reducing the number of mechanical components and easing troubleshooting. Features include: • Air/Fuel Ratio Control (AFRC) • Electronic ignition • Electronic governing/speed control • Start/stop logic • Engine protection & monitoring

Full Range of Attachments

Large variety of factory-installed engine attachments reduces packaging time

Gas Engine Rating Pro (GERP)

GERP is a web-based program designed to provide site performance capabilities for Cat® natural gas engines for the gas compression industry. GERP provides engine data for your site's altitude, ambient temperature, fuel, engine coolant heat rejection, performance data, installation drawings, spec sheets, and pump curves.

Product Support Offered Through Global Cat Dealer

More than 2,200 dealer outlets Cat factory-trained dealer technicians service every aspect of your petroleum engine Caterpillar parts and labor warranty. Preventive maintenance agreements available for repairbefore-failure options S•O•SSM program matches your oil and coolant samples against Catepillar set standards to determine: - Internal engine component condition - Presence of unwanted fluids - Presence of combustion by-products - Site-specific oil change interval

Over 80 Years of Engine Manufacturing Experience

Over 60 years of natural gas engine production Ownership of these manufacturing processes enables Caterpillar to produce high quality, dependable products. - Cast engine blocks, heads, cylinder liners, and flywheel housings - Machine critical components - Assemble complete engine

Web Site

For all your petroleum power requirements, visit www.cat.com/oilandgas.

Engine Specifications

| Maximum Rating | 95.0BHP |

| Rated Speed | 1800rpm |

| Emissions | Rich Burn: EPA NSPS Site Compliant Capable with Caterpillar or Customer Supplied AFRC & Aftertreatment |

| Minimum Rating | 95.0BHP |

| Compression Ratio | 10.5:1 |

| Aspiration | Naturally Aspirated |

| Rotation from Flywheel End | Counterclockwise |

| Flywheel and Flywheel Housing | SAE No. 1 |

| Flywheel Teeth | 156 |

| Weight - Dry | 2253.8lb |

| Displacement | 425.0in³ |

| Oil Change Interval | 750 |

| Ignition, Protection | ADEM™ A4 |

| Air/Fuel Ratio Control | ADEM™ A4 |

| Stroke | 6.0in |

| Bore | 4.75in |

| Length | 46in |

| Width | 29in |

Capacity for Liquids

| Cooling System | 4.23gal (US) |

| Lube Oil System - Refill | 8.19gal (US) |

Standard Equipment

Air Inlet System

- Air cleaner — intermediate duty, dry

- Air cleaner rain cap (shipped loose)

- Service indicator

Control System

- ADEM A4

Cooling System

- Thermostats and housing — full open temperature 97°C (207°F)

- Jacket water pump — gear-driven, centrifugal, non-self-priming

Exhaust System

- Exhaust manifolds — watercooled

- Exhaust elbow — dry 102 mm (4 in)

- Three-way catalyst — 1.0 g and 0.5 g NOx catalyst options

Flywheels & Flywheel Housings

- Flywheel, SAE No. 1

- Flywheel housing, SAE No. 1

- SAE standard rotation

Fuel System

- Air/fuel ratio control

- Gas pressure regulator

- Requires 10.3-68.9 kPa (1.5-10 psi) gas

- Natural gas carburetor

Ignition System

- ADEM A4 ignition

Lube System

- Crankcase breather, top mounted

- Oil cooler

- Oil filter

- Oil pan, full sump

- Oil filler and dipstick

Protection System

- The following parameters include alarm and shutdown

Optional Equipment

Charging Alternator

- 24V, 35A alternator

- 24V, 35A CSA alternator*

Cooling System

- Radiators

- Jacket water pump inlet adapter

Exhaust System

- Exhaust flex fitting — ANSI flange

- Exhaust elbow

- Catalyst harness

- ANSI flange

Ignition System

- CSA certified electronics and ignition*

Instrumentation

- Operator interface panel

- Operator interface panel enclosure

- 15', 25' and 50' interconnect harness

Starting System

- Air pressure regulator

- Air start silencer

- Vane starter

- Electric starter

- Turbine starter