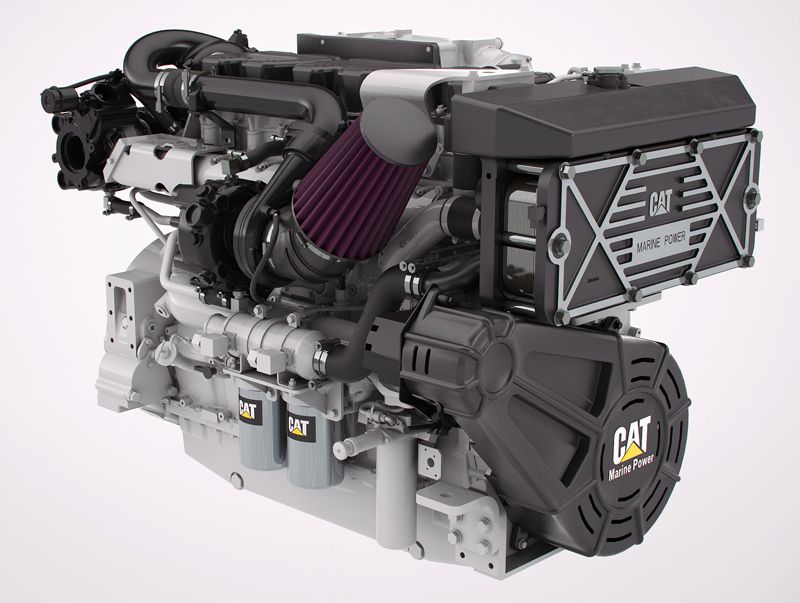

Cat C18 High Performance Propulsion Engine - Recreational

THE RUNDOWN

Separate circuit aftercooling system

The primary advantage of the separate circuit aftercooling system (SCAC) is that no sea water circulates through the aftercooler

Emissions

EPA Tier 3 compliant, IMO II and EU IWW compliant

Cooling system

Heat exchanger and Keel cooled options for all ratings

Turbo Configurations

Single turbo configurations for all ratings

Competitive size and weight

Marine Certifications

All major MCS type approvals available from factory

Ratings

| Power Range | 803 - 1136 bhp, 599 - 847 bkW |

Engine

| Speed Range | 2300 rpm |

| Emissions | EPA Tier 3, IMO II |

| Aspiration | TA,TTA |

| Bore | 5.7in |

| Stroke | 7.2in |

| Displacement | 1106.0in³ |

| Rotation from Flywheel End | Counterclockwise |

| Configuration | In-line 6, 4-Stroke-Cycle Diesel |

Dimensions & Weights

| Maximum Height | 51.2in |

| Maximum Dry Weight | 4299.0lb |

| Maximum Width | 47.4in |

| Maximum Length | 76.0in |

| Minimum Length | 73.0in |

| Minimum Dry Weight | 4000.0lb |

| Minimum Width | 44.6in |

| Minimum Height | 47.2in |

Standard Equipment

AIR INLET SYSTEM

- Aftercooler - sea water, corrosion resistant

- Air cleaner/fumes disposal (closed system)

- Turbocharger, jacket water cooled

- Front-down and rear-down aftercooler condensate drains

CONTROL SYSTEM

- Electronic diagnostics and fault logging

- Cold mode start strategy

- Engine and transmission monitoring (speed, temperature, pressure)

- Electronic fuel/air ratio control

- 70-pin customer connector

- Engine Protection Mode for High Ambient Conditions

- Three types of throttle inputs (primary/ secondary PWM, 0-5V, 4-20mA +/-)

COOLING SYSTEM

- Sea water pump, rubber impeller, self-priming, gear driven

- Sea water aftercooled

- Jacket water pump, gear driven

- JW Heat Exchanger - Titanium plate with integral fuel cooler expansion tank, and thermostat housing (fully open temp 92C)

- Coolant recovery system

EXHAUST SYSTEM

- Water-cooled exhaust manifold & turbocharger

- 114.3 mm (4.5 in) ID round flanged exhaust outlet

FLYWHEELS & FLYWHEEL HOUSINGS

- Flywheel Housing, SAE No. 1

- Flywheel, 18 inch, 113 teeth

- SAE standard rotation

FUEL SYSTEM

- Fuel filter, RH service on Port, LH service on Starboard

- Fuel transfer pump

- Fuel priming pump

- Hybrid fuel line design

LUBE SYSTEM

- Crankcase breather

- Oil cooler

- Oil filter, spin-on, low profile, RH service on Port, LH service on

- Oil pan, center sump

- Dipstick, RH service on Port, LH service on Starboard

- Oil pump, gear driven

POWER TAKE-OFFS

- Hydraulic pump drive, SAE A, 11-tooth spline, 46 ft-lbs max torque, counterclockwise as viewed from the front of the engine with 1.41 x engine speed

PROTECTION SYSTEM

- A4 ECM Electronic Engine Monitoring System provides customer programmable engine de-rate strategies to protect against adverse operating conditions

GENERAL

- Front damper guard

- Lifting eyes

- RH or LH service options

- Upper rear-facing customer wiring connector and Service Tool connection

Optional Equipment

CHARGING SYSTEM

- Battery Chargers

- Charging Alternators 24 Volt 70/105 AMP

- Alternator Mounting Group

FUEL SYSTEM

- Primary Fuel Filter / Water Separator

- Primary Fuel Filter

LUBE SYSTEM

- Transmission Oil Cooler

POWER TAKE-OFFS

- Crankshaft Pulleys

STARTING SYSTEM

- Electric Starting Motor - Single 24 Volt

- Battery Sets - 24 Volt - Dry

CONTROL SYSTEM

- MECP I

INSTRUMENTATION

- OEM Wiring Harness

- Engine to Engine Harness

- Instrument Panels

- Transmission Sensors