950 GC Wheel Loader | Front Loader

The purpose-built, easy to operate, reliable Cat 950 GC wheel loader is right-sized to get your everyday jobs done. With low fuel consumption, low owning and operating costs, the 950 ...

Engine

- Net Power - ISO 9249

- 225HP

- Emissions

- Tier 4/Stage V

- Note

- The air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a (Global Warming Potential = 1430). The system contains 1.9 kg (4.2 lb) of refrigerant which has a CO2 equivalent of 2.717 metric tonnes (2.995 tons).

- Bore

- 4.13in

- Stroke

- 5.31in

- Peak Gross Torque - 1,400 rpm - ISO 14396

- 805ft·lbf

- Peak Gross Torque - 1,400 rpm - SAE J1995

- 811ft·lbf

- Maximum Power - 1,700 rpm - SAE J1995

- 241HP

- Maximum Power - 1,700 rpm - ISO 14396 - Metric

- 243HP

- Maximum Power - 1,700 rpm - ISO 14396

- 240HP

- Maximum Net Power - 1,700 rpm - SAE J1349

- 225HP

- Maximum Net Power - 1,700 rpm - ISO 9249 - Metric

- 228HP

- Maximum Net Power - 1,700 rpm - ISO 9249

- 225HP

- Displacement

- 428in³

- Engine Model

- Cat C7.1

Weights

- Operating Weight

- 41554lb

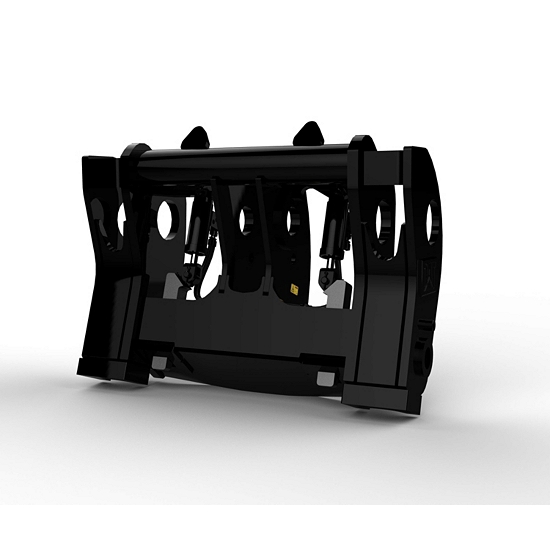

Buckets

- Bucket Capacities

- 2.9-4.4 m³ (3.75-5.75 yd³)

Dimensions

- Centerline of Rear Axle to Hitch

- 5.42ft

- Wheel Base

- 10.83ft

- Height - Top of Hood

- 8.75ft

- Height - Top of Exhaust Pipe

- 11.17ft

- Height - Top of ROPS

- 11.33ft

- Note

- All dimensions are approximate and based on MAXAM MS302 23.5R25 L3 radial tires.

- Centerline of Rear Axle to Edge of Counterweight

- 6.75ft

- B-Pin Height

- 13.75ft

- Rack Back - Maximum Lift

- 60 degrees

- Rack Back - Carry

- 45 degrees

- Rack Back - Ground

- 40 degrees

- Lift Arm Clearance

- 12ft

- Ground Clearance

- 1.5ft

Transmission

- Note

- Maximum travel speed in standard vehicle with empty bucket and standard L3 tires with 760 mm (30 in) roll radius.

- Reverse - 3

- 14.2mile/h

- Reverse - 2

- 8mile/h

- Reverse - 1

- 4.5mile/h

- Forward - 4

- 22.4mile/h

- Forward - 2

- 8mile/h

- Forward - 3

- 14.2mile/h

- Forward - 1

- 4.5mile/h

Sound

- With Cooling Fan Speed at 70% of Maximum Value - Operator Sound Pressure Level (ISO 6396:2008)**

- 73dB(A)

- With Cooling Fan Speed at 70% of Maximum Value - Exterior Sound Power Level (ISO 6395:2008)**

- 107 LWA***

- Note (3)

- ***European Union Directive "2000/14/EC" as amended by "2005/88/EC."

- Note (2)

- **For machines in European Union countries and in countries that adopt the "EU Directives."

- Note (1)

- *Distance of 15 m (49.2 ft), moving forward in second gear ratio.

- With Cooling Fan Speed at Maximum Value - Operator Sound Pressure Level (ISO 6396:2008)

- 73dB(A)

- With Cooling Fan Speed at Maximum Value - Exterior Sound Pressure Level (SAE J88:2013)

- 76 dB(A)*

- With Cooling Fan Speed at Maximum Value - Exterior Sound Power Level (ISO 6395:2008)

- 109dB(A)

- With Cooling Fan Speed at 70% of Maximum Value: Note (1)

- For machines in European Union countries and in countries that adopt the EU Directives

- With Cooling Fan Speed at 70% of Maximum Value: Note (2)

- European Union Directive "2000/14/EC" as amended by "2005/88/EC."

- With Cooling Fan Speed at Maximum Value - Note

- Distance of 15 m (49.2 ft), moving forward in second gear ratio.

Service Refill Capacities

- Transmission

- 11.9gal (US)

- Differential - Final Drives - Rear

- 10gal (US)

- Differential - Final Drives - Front

- 10.6gal (US)

- DEF Tank

- 4.2gal (US)

- Crankcase

- 4.8gal (US)

- Cooling System

- 13.2gal (US)

- Fuel Tank Size

- 76.6gal (US)

- Hydraulic Tank

- 29.6gal (US)

Hydraulic System

- Implement System - Maximum Pump Output at 2,390 rpm

- 68gal/min

- Implement System - Maximum Operating Pressure @ 50 ± 1.5 L/min (13.2 + 0.4 gal/min)

- 4047psi

- Hydraulic Cycle Time - Total Cycle Time

- 9.4s

- Steering System - Pump Type

- Piston

Weights and Operating Specifications

- Operating Weight

- 41554lb

- Tipping Load - Full Turn - ISO 14397-1*

- 24264lb

- Tipping Load - Full Turn - Rigid Tires**

- 25875lb

- Breakout Force

- 34638lbf

- Note (1)

- For 3.1 m3 (4.0 yd3) general purpose buckets with BOCE. Weight based on a machine configuration with MAXAM MS302 23.5R25 L3 radial tires, full fluids, operator, standard counterweight, cold start, roading fenders, Product Link™, secondary steering, sound

- Note (2)

- *Full compliance to ISO (2007) 14397-1 Sections 1 thru 6, which requires 2% verification between calculations and testing.

- Note (3)

- **Compliance to ISO (2007) 14397-1 Sections 1 thru 5.

Engine - Tier 4 Final/Stage IV

- Emissions

- Tier 4/Stage IV

RELIABILITY YOU CAN COUNT ON

- Cat® C7.1 engine offers increased power density with a combination of proven electronic, fuel, and air systems.

- Equipped with automatic Cat regeneration system, Cat Clean Emissions Module (CEM) with Diesel Particulate Filter (DPF), and Diesel Exhaust Fluid (DEF) tank and pump.

- Thorough component design and machine validation processes result in unmatched reliability and uptime.

ACHIEVE GREATER PRODUCTIVITY

- The proven Cat Z-bar linkage geometry with Performance Series Buckets offer excellent penetration into the pile and high breakout forces. Combined with best-in-class standard dump clearan ce, this results in low fuel consumption and exceptional production capabilities.

- Cat designed, electronically controlled, automatic powershiftcountershaft transmission features shift protection and is equipped with a split flow oil system for efficiency, durability, and smoother gear changes.

- Optional Fusion™ quick-coupler control features a selectable kickout to adjust for efficient bucket and fork applications.

DO MORE WITH LESS FUEL

- Engine Idle Management System (EIMS) and Auto Engine Idle Shutdown (EIS) maximize fuel efficiency by reducing engine rpm after a specified amount of idle time.

- Electronically controlled, hydraulically driven variable speed fan adjusts to meet the varying cooling requirements of the machine. This results in a reduced average fan speed, lowering fuel consumption, noise levels, and radiator plugging.

- Load sensing hydraulics produce flow and pressure for theimplement system upon demand and only in amounts necessary to perform the needed work functions. This state-of-the-art system results in low fuel consumption.

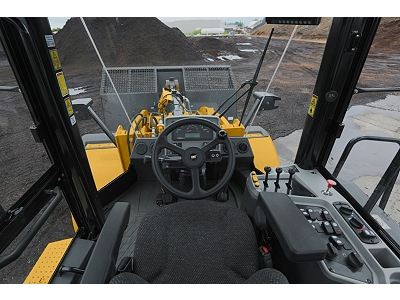

DESIGNED FOR OPERATORS

- The spacious cab features easy, intuitive controls and excellent visibility which provides a comfortable working environment for efficient all day operation.

- Pilot-operated hydraulic implement controls deliver comfortable, low-effort operation. Two single-axis levers or one joystick are available. Both arrangements are equipped with kick-down switches.

- The adjustable steering column includes the F-N-R shifter and turn signal control lever.

- Unmatched viewing area with a wide, flat, and distortion-free front windshield.

- The glass stretches to the floor of the cab for excellent visibility to the bucket and front tires.

- The cab roof has channels which direct rain off the corners of the cab, keeping windows clear.

- Air conditioning system is standard. Ten louvered vents allow the operator to direct the air flow to remain productive and efficient all shift long.

SAFELY HOME EVERY DAY

- Ladders are standard on both sides of the machine to easily access the platforms.

- Platforms are equipped with guard- and handrails for safe access to the cab.

- The main cab door opens to the front and provides wide access to the operator environment.

- Front and back wipers ensure that a clear view is maintained.

- External rearview mirrors with integrated spot mirrors arestandard.

- A rear vision camera is standard to clearly monitor movement behind the machine.

- Hinged wheel guards, easy removal/re-install.

- Optional windshield and power train guards.

SAVE ON SERVICE AND MAINTENANCE

- Grouped service points and sight gauges allow for easy daily maintenance.

- Convenient access to left, right, and rear of engine compartment provides excellent serviceability.

- Electrical and hydraulic service centers, along with additional key serviceability features, help make servicing and in-field component exchange quick, easy, and efficient.

- A rear swing-up grill gives easy cleaning access to thecooling cores.

- Optional integrated Cat Autolube system provides full lube system monitoring and diagnostic test visibility. One-button control, including fault flash function.

- Caterpillar design and manufacturing techniques assureoutstanding service life.

CAT PRODUCTION MEASURMENT KIT

- This optional kit is simple to install compared to other 3rd party payload systems*.

- On-the-go weighing** for precise load targets with provenaccuracy, flexible installation, and easy calibration and setup.

- Brings payload weighing to the cab so operators can work more productively and deliver consistently accurate loads.

- Increases productivity, weighing while lifting with no interruptions in loading cycle.

- High efficiency: load to exact specification, load more trucks faster, and move more material for more revenue.

- Improve efficiency with less rework; save time, labor, fuel,and costs.

* Not available in all markets

** Not legal for trade